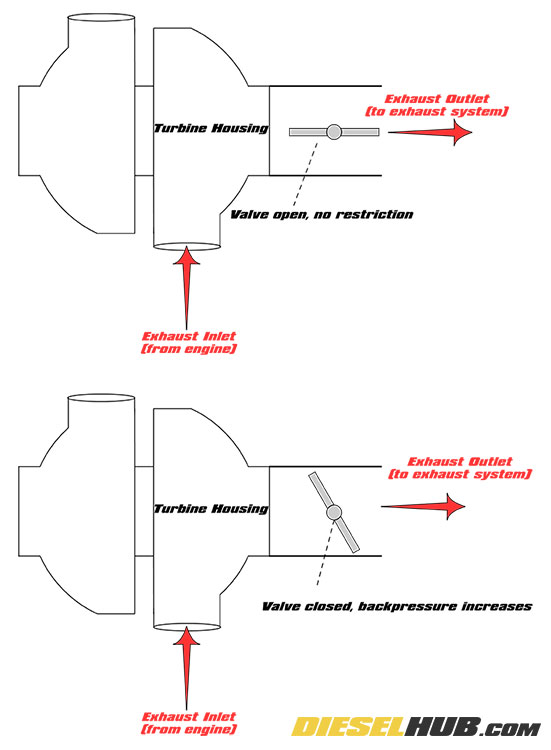

How Exhaust Brakes Work

Exhaust brakes help a truck slow down by restricting exhaust flow. Exhaust brakes are generally installed directly behind the turbocharger turbine outlet, but can be installed virtually anywhere in the exhaust system. A simple exhaust brake consists of a butterfly valve inside of a tubular housing. A solenoid or mechanical attachment opens/closes the exhaust brake as necessary. In the open position, exhaust flows normally. In the closed or partially closed position, exhaust backpressure is greatly increased. The backpressure works against the engine as it pumps air out of the cylinders, helping to slow down the engine and therefore the vehicle. Some exhaust brakes are completely mechanical, while others communicate directly with the engine's PCM (computer) to provide precision on-demand braking. Exhaust brakes are great for controlling speeds when towing downhill or bringing heavy loads to a halt while saving the truck and trailer brakes by reducing use.

| Exhaust Brake Pros | Exhaust Brake Cons |

| Provides better control of vehicle speed when hauling and towing, especially on downhill grades | Presents a small restriction in the exhaust system - negligible for most trucks when the exhaust brake valve is in the open position |

| Reduces truck and trailer brake wear | |

| Helps prevent truck and trailer brakes from overheating | |

| Decreases distance in which a truck and trailer can be stopped, particularly beneficial in an emergency situation |

Exhaust leaks before the location of the exhaust brake should be repaired to ensure maximum efficiency. A marginal sacrifice in performance may accompany the install, but it's negligible unless you're looking for total performance. The trade-off is well worth it if you use your truck for its intended purpose. Exhaust brakes are available for a variety of applications, although some naturally aspirated engines may not be compatible.