The heart of a Piezo (short for piezoelectric) injector is the Piezo crystal. When electricity is applied across the crystal, it rapidly expands, thus making it suitable to act as the actuator in a diesel fuel injector. According to Bosch, who introduced Piezo injectors to the industry, a Piezo actuator acts up to 5 times faster than a standard injector solenoid and the motion is frictionless. This translates into precise fuel measurement and allows for multiple injector events to occur per combustion cycle.

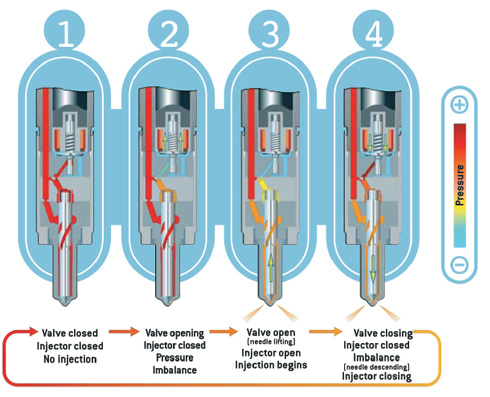

Because Piezo injectors are used in common rail injection systems, high pressure fuel is constantly delivered to the tip of the injector where a needle rests and blocks fuel from being injected. Pressurized fuel is delivered to the top of this needle as well, the force of which keeps the needle closed. When the Piezo crystal is energized, a valve at the top of the needle opens, allowing the pressurized fuel at the top of the needle to return to the tank through the return line. With no pressure at the top of the needle, it springs open, allowing fuel to be injected into the combustion chamber. When the Piezo actuator is de-energized, the valve closes and high pressure fuel forces the needle to return to the closed position. The injection process occurs extremely fast.

Source: Renault

The greatest advantage of Piezo injectors is the rate and precision in which fuel can be delivered, since the actuator can be rapidly activated and deactivated. Piezo injectors are also known for their superior reliability. The result is increased longevity, durability, efficiency, and reduced emissions.