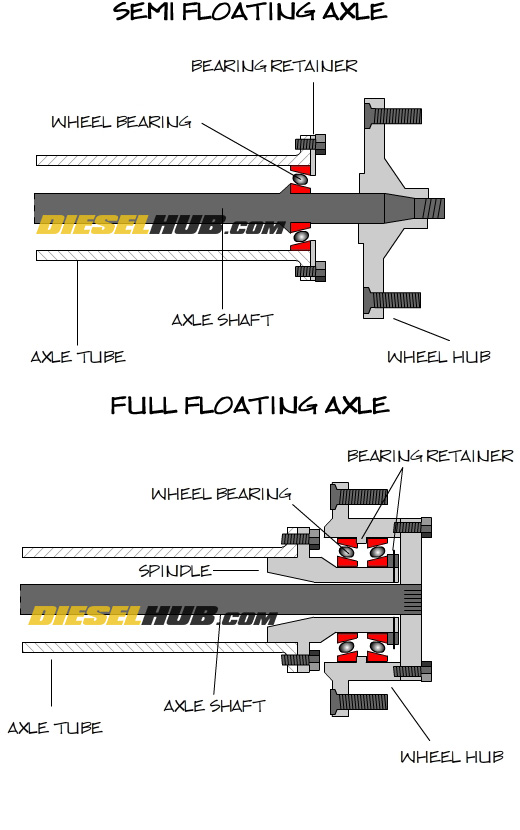

Semi Floating Axle

By design, a semi floating axle uses a wheel hub that is directly connected to the axle shaft (the hub and axle shaft are commonly a single part), which is supported by a bearing located near the wheel end of the axle tube. As such, the weight of the vehicle and any cargo must be carried by the axle shaft itself at this point. Therefore, the axle shaft is used to transmit power to the wheel as well as support the load of the vehicle, applying a bending moment, shear force, and torsional force to the axle shaft. Semi floating axles are both lighter in weight and cheaper to manufacture than full floating axles, though they have a limited load capacity. They are the axle of choice in light duty vehicles, including midsize and 1/2 ton pickup trucks.

Full Floating Axle

A full floating axle consists of a wheel hub assemble that is separate from the axle shaft. A spindle bolted to the axle tube supports the wheel hub by means of a pair of wheel bearings. Therefore, the weight of the vehicle and its cargo is transfered to the axle tube, rather than the axle shaft itself. As a result, a full floating axle shaft is not subjected to the bending moment or shear force that a semi floating axle is. Rather, the axle shaft's only task is to transmit power to the wheel hub. As a result, the shaft is only subjected to torsional loads (for all intents and purposes). Full floating axles are rather heavy, but have very large weight carrying capacities. They are common on 3/4 ton and heavier trucks, which require the ability to transport considerable weight.

To increase the capacity of a semi floating axle, the axle shaft diameter would have to be increased, where as the spindle and wheel hub design determine, for the most part, the carrying capacity of a full floating axle. The diagram below provides a rough comparison between semi and full floating axles. Note that this is not a blueprint of any particle axle and therefore real-world designs will vary depending on the axle.