GM's government contracts continued, and though 2002 was the final model year of the 6.5L for GMC and Chevy, engine production continued through Humvee manufacturer AM General under license from General Motors. The 6.2L and 6.5L diesels are dimensionally similar, and thus most exterior bolt-on components are interchangeable between the two engines. Like its predecessor, the 6.5L bellhousing bolt pattern and engine mounts are identical to those of GM V-8 gasoline engines.

6.5L GM Diesel Specs

| Manufacturer | Detroit Diesel Corporation | |

| Production Years | 1992-2002; currently still used in military applications, produced by AM General | |

| Applications | Chevrolet/GMC: Tahoe, Yukon, Suburban, C/K pickups, 1500, 2500, & 3500 trucks. AM General: Hummer & HMMWV |

|

| Configuration | 90° V-8 | |

| Block/Head Material | Cast iron block, cast iron heads | |

| Displacement | 395 cubic inches, 6.5 liters | |

| Firing Order | 1-8-7-2-6-5-4-3 | |

| Cylinder Numbers |  |

|

| Compression | 18:1 to 21.5:1 depending on year & application | |

| Compression Test Pressure | Minimum 380 psi (dry test, do NOT perform a wet compression test). Cylinder with lowest pressure should be within 80% of cylinder with highest pressure. | |

| Bore | 4.055 inches | |

| Stroke | 3.818 inches | |

| Injection | IDI (indirect injection) Stanadyne DB-2 injection pump (naturally aspirated engines) Stanadyne DS-4 injection pump (turbocharged models, features PMD/FSD) |

|

| Aspiration | Turbocharged and naturally aspirated versions produced; turbocharger models as follows: | |

| 1992 pickup | BorgWarner GM-1 | |

| 1993 pickup | BorgWarner GM-3 | |

| 1994 - 1995 pickup | BorgWarner GM-4 | |

| 1996 pickup | BorgWarner GM-5 | |

| 1997 - 2002 pickup | BorgWarner GM-8 | |

| Hummer/van, all MY | BorgWarner GM-6 | |

| Oil Capacity* | 7 qts w/ filter up to 1998 model year, 8 qts w/ filter 1999+ model year. Use oil filter ACDelco PF1218, all model years. | |

| Max Engine Speed | 3,400 rpm (governed engine speed may be as low as 3,000 rpm in certain applications) | |

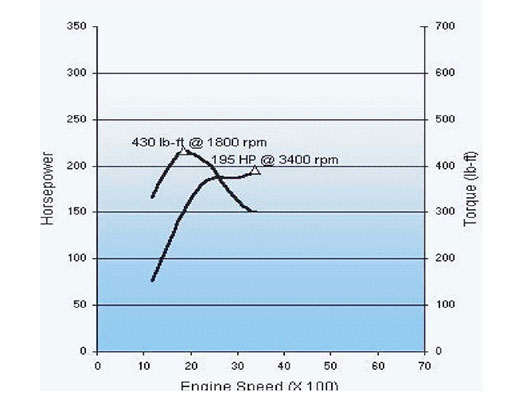

| Horsepower | • 180 hp @ 3,400 rpm (introductory) • 215 hp @ 3,200 rpm (max) |

|

| Torque | • 360 lb-ft @ 1,700 (introductory) • 440 lb-ft. @ 1,800 rpm (max) |

|

| Engine Weight | Approx. 750 lbs | |

| Nominal Engine Dimensions | Length | 30 inches |

| Width | 26 inches | |

| Height | 26 inches | |

* Always check oil level after refilling crankcase.

The 6.5L Detroit diesel maintained the fuel efficient image that was used to market its predecessor. A variety of applications used the 6.5L, and as such several versions were produced. Common 6.5L problems include cracks propagating in the main caps and crankshaft failures from aging/fatigue of the harmonic balancer. Overheating issues are also common, and have been known to lead to cracked cylinder heads amongst other failures. The 6.5L diesel was retired to make way for GM/Isuzu's Duramax diesel, launched for the 2001 model year.

6.5L Diesel Variations and RPO Codes

| Variation | Description |

| L49 | Naturally aspirated, standard engine |

| L56 | Turbocharged, emissions controlled (EGR & catalytic converters); used in all light duty 1/2 & 3/4 ton trucks |

| L57 | Naturally aspirated, high output (HO) |

| L65 | Turbocharged, heavy duty 3/4 & 1 ton trucks, high output (HO) |

6.5L Diesel Horsepower & Torque Curve

6.5L Diesel Oil Spec and Service Intervals

For all model year 6.5L turbocharged and naturally aspirated diesels the engine oil and filter is required to be changed every 5,000 miles/12 months under normal operating conditions or every 2,500 miles/3 months under severe operating conditions (periods of excessive idle, towing, frequent short trips, stop-and-go traffic, etc).

| Oil Viscosity | Acceptable Temperature Range | Notes |

| SAE 30 | ambient temperature > 32° F | Recommended in consistently hot ambient temperatures. Not preferred in cooler temperatures, use 15W-40. |

| SAE 15W-40 | ambient temperature > 0° F | Preferred viscosity within temperature range unless ambient temperature is consistently hot. |

| SAE 10W-30 | ambient temperature < 60° F | Required cold weather viscosity. |

In addition to adhering to the engine oil viscosity chart above, the following block heater schedule should be used in cold weather:

| Oil Viscosity | Ambient Temp > 32° F | Ambient Temp 32° F to 0° F | Ambient Temp < 0° F |

| SAE 30 | block heater not required | use block heater min 2 hours | use block heater min 8 hours |

| SAE 15W-40 | block heater not required | block heater not required | use block heater min 8 hours |

| SAE 10W-30 | block heater not required | block heater not required | use block heater min 8 hours |

6.5L Diesel PMD/FSD Failures

PMD failures are arguably the most commonly experienced problem with the 6.5L diesel. The PMD, or Pump Mounted Driver is an electronic module affixed to the side of the injection pump that controls the fuel solenoid. It is also often referred to as the FSD, or Fuel Solenoid Driver. The PMD's fatal flaw is its location on the driver side of the injection pump, which sits in the engine valley. While energized, the PMD generates an intense amount of heat, which does not properly dissipate (do to its location) and ultimately leads to the module's demise. Most hard start, no start, and engine stalling concerns are attributed to a failed or failing PMD. It is extremely common for owners to mount the driver in a remote location and/or install an aftermarket heat sink to a relocated PMD to keep it from overheating. While the PMD/FSD is certainly the 6.5 diesel's Achilles heal, concerns are easily remedied thanks to response from the aftermarket.