6.5L Diesel Wastegate Solenoid Part NUmbers

| Part Description | Part Number(s) | Remarks/Notes | |

| Wastegate solenoid, 1994 - 1997 models | w/ vent filter | ACDelco 214-637 | --- |

| w/o vent filter | ACDelco 214-1073 | ||

| Wastegate solenoid, 1998+ models | ACDelco 214-637 | --- | |

| Wastegate solenoid connector, all models | RT-201101 | [1] | |

[1] Recommend connector be replaced if damaged or wires exposed.

6.5L Diesel Wastegate Operation, Diagnostics, & Replacement Procedures

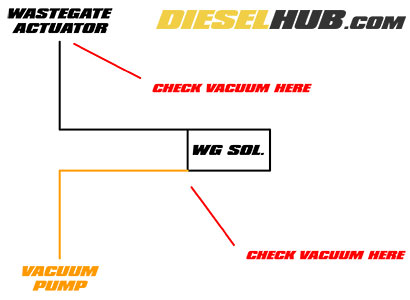

The wastegate solenoid on turbocharged 6.5L diesels is located on the driver side valve cover. It actuates the turbocharger wastegate by controlling vacuum supplied to the wastegate actuator by the vacuum pump. The wastegate actuator is connected to the wastegate valve in the turbine housing by means of an external linkage. A wastegate is used to control turbocharger boost by bypassing exhaust flow across the turbine wheel itself once maximum pressure is achieved. It is then opened or closed as necessary to maintain boost pressure in the intake manifold. The system consists of the vacuum pump, the wastegate solenoid, and the wastegate actuator. Vacuum lines connect the vacuum pump to the wastegate solenoid and the wastegate solenoid to the wastegate actuator.

The correct vacuum specification at the wastegate solenoid (coming from the vacuum pump) and wastegate actuator (downstream of the wastegate solenoid) is 15 in-Hg (~7.5 psi) at idle. If an engine code is present for the wastegate solenoid, replace the solenoid. The vacuum lines do not often crack but should be checked in addition to the following vacuum tests.

The wastegate solenoid is similar in appearance to the EGR solenoid on EGR equipped trucks. The factory ACDelco wastegate solenoids have a green dot on the top of them, distinguishing them from the EGR solenoids.

Click any thumbnail to view high resolution, fullsize image w/ details

• Locate the wastegate actuator linkage and verify that it is free to move. If the linkage is stuck, the problem is unlikely to have any relationship to the wastegate solenoid and the turbocharger may require service. You may also attempt to lubricate the linkage if it seems to stick; it should operate relatively freely.

• The wastegate solenoid is mounted to the driver side valve cover. There are two vacuum lines entering the solenoid, one of which comes from the vacuum pump (mounted on the passenger side front of the engine) while the other runs from the wastegate solenoid to the wastegate actuator.

Note - this is a non-EGR engine. EGR equipped engines will have several solenoids mounted to the valve cover; the wastegate solenoid has a green dot on top.

• With the engine off, unplug the vacuum lines at the wastegate solenoid.

• Install a vacuum gauge on the line coming from the vacuum pump. You'll need to affix a nipple to the vacuum gauge if one is not already installed.

• Start the engine and read the vacuum from the vacuum pump line. A minimum 15 in-Hg (inches Mercury) or roughly 7.5 psi is necessary for proper wastegate actuation. A good pump will typically read in the 20 to 25 in-Hg range.

• Turn the engine off, remove the vacuum gauge, and reinstall the vacuum lines to the wastegate solenoid.

• Disconnect the vacuum line from the wastegate actuator. Note that the wastegate actuator may be mounted below the compressor housing (as pictured) or on the side of the turbine housing (not pictured).

• Install the vacuum gauge on the vacuum line and start the engine. The vacuum specification at this point is identical to that provided in the prior step.

• If the vacuum pump meets this specification but the line at the wastegate actuator does not, the wastegate solenoid needs to be replaced or the line is cracked. If the vacuum pump does not meet the vacuum specification, it needs to be replaced.

• Replacing the wastegate solenoid takes mere minutes. Disconnect the vacuum line and electrical connector, then remove the single bolt securing the solenoid with a 10 mm socket. Replace in reverse.