Ford Motor Company begin phasing in the 6.0L Power Stroke during the 2003 model year as the 7.3L Power Stroke was being phased out. Both engine platforms were available simultaneously during the 2003 model year as Ford used up its stock of 7.3 liters, but only the 6.0 liter Power Stroke was available when the 2004 model year trucks began rolling off assembly lines. The highly advanced 365 cubic inch turbodiesel boasted a refined HEUI injection system and quick-spooling variable geometry turbocharger. This allowed the new engine platform to exceed its predecessor in the performance department by a modest margin, boasting a peak 325 horsepower and 560 lb-ft or torque.

An exhaust gas recirculation system and diesel oxidation catalyst helped the engine meet relevant emissions regulations, and its smaller displacement promised greater fuel efficiency in addition to aiding in emissions related hurdles. The engine was available with Ford's [then] new five speed TorqShift transmission or the ZF S6-750 six speed manual transmission, the later of which had been employed in previous applications and carried a certain niche following.

Woefully, the 6.0L Power Stroke proved troublesome for Ford and its reliability fell short of that expected from the "Power Stroke" namesake, a reputation built on the 7.3's persistent tenacity in various application types and deployments endured during its 10 year tenure. Recalls and service bulletins flooded Ford's dealerships and repair facilities as technicians scrambled to identify and repair various issues with the new engine platform developed and manufactured by International-Navistar.

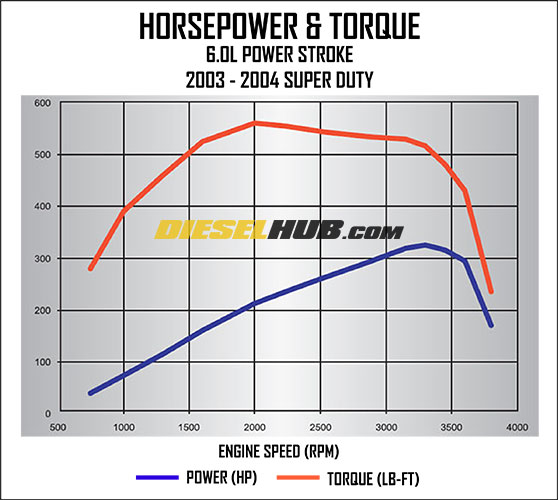

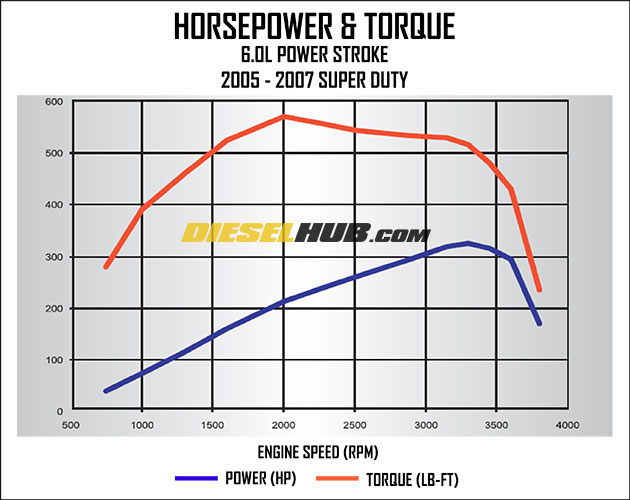

Despite its flaws, the 6.0L Power Stroke was featured as one of Ward's 10 Best engines for 2003 in their annual top 10 review of the automotive industry. While torque does not peak on the 6.0L Power Stroke until 2,000 rpm, its torque curve is relatively broad and the engine is well suited for towing. The engine platform was ultimately retired following the 2007 model year to make way for the International-Navistar 6.4L Power Stroke, which was equipped to meet more stringent emissions requirements going into effect in the United States. While the 6.4.L Power Stroke wouldn't necessarily prove significantly better, it would point Ford Motor Company in the right direction.

6.0 Powerstroke Engine Specs

| Engine | 6.0L Power Stroke, International VT-365 | |

| Type & Configuration | 4 stroke diesel, 90° V8 | |

| Applications | 2003 - 2007 Ford F-250, F-350, F-450, F-550 Super Duty pickup & chassis cab trucks 2003 - 2005 Ford Excursion 2004 - 2010 Ford Econoline E-350, E-450 2003 - 2008 Ford F-650, F-750 medium duty trucks 2003 - 2012 International medium duty trucks (various models, VT-365) |

|

| Advertised Displacement | 6.0 liters, 365 cubic inches | |

| Calculated Displacement | 5.95 liters, 363.14 cubic inches | |

| B10 Life | 250,000 miles | |

| B50 Life | Not rated | |

| Bore | 3.74 inches (95.00 mm) | |

| Stroke | 4.134 inches (105.00 mm) | |

| Bore/Stroke Ratio | 0.90 (undersquare) | |

| Compression Ratio | 18.0:1 | |

| Firing Order | 1-2-7-3-4-5-6-8 | |

| Cylinder Numbers |  Cylinders 1, 3, 5, 7 located on the passenger side bank; cylinders 2, 4, 6, 8 located on driver side bank |

|

| Engine Block Material | Cast iron | |

| Cylinder Head Material | Cast iron | |

| Head Bolt Type/Count | M14 torque-to-yield (TTY) head bolts, 4 bolts per cylinder | |

| Injection System | Direct injection, Electro Hydraulic Generation Two (G2) injection technology (HEUI injectors, 26,000 psi) | |

| Aspiration | Turbocharged & intercooled; single Garrett GT3782VA variable geometry turbocharger (VGT), hydraulically actuated vanes | |

| Reciprocating Assembly | Induction hardened crankshaft bearing surfaces | |

| Valvetrain | Conventional cam-in-block overhead valve setup; gear driven camshaft with 4 valves per cylinder (32 valve) | |

| Cold Start Aid(s) | Glow plug preheat system, 1 glow plug per cylinder located in combustion chamber | |

| Engine Oil Capacity | 15 U.S. quarts with filter [1] | |

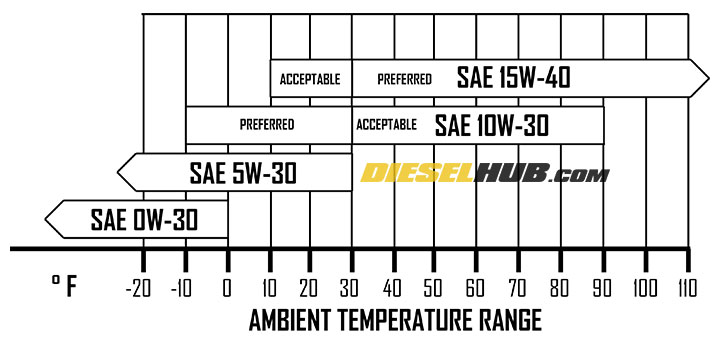

| Engine Oil Spec | SAE 15W-40, SAE 10W-30, SAE 5W-30, SAE 0W-30; see ambient temperature breakdown & API requirements in complete viscosity chart below | |

| Lube Oil Filter P/N | Motorcraft FL-2016 | |

| Fuel | Ultra low sulfur diesel fuel (#1, #2, or winterized blends) Biodiesel blends greater than B5 (5% biodiesel) not recommended |

|

| Fuel Filter P/N | Motorcraft FD-4616 (kit, includes primary & secondary filter, all o-rings) | |

| Horsepower | 325 hp @ 3,300 rpm [2] | |

| Torque | 2003 - 2004 model years | 560 lb-ft @ 2,000 rpm [2] |

| 2005 - 2007 model years | 570 lb-ft @ 2,000 rpm [2] | |

| Idle Speed | Approximately 670 rpm | |

| Governed Speed | Approximately 4,200 rpm (max shift speed approximately 3,600 rpm in automatic equipped trucks) | |

| Emissions Equipment | Exhaust gas recirculation (EGR) and diesel oxidation catalyst (DOC) | |

| Coupled Transmissions | Ford 5R110W TorqShift five speed automatic, ZF S6-750 six speed manual transmission [3] | |

| Engine Weight | Approximately 966 lbs with engine oil | |

| Engine Dimensions | Length | 35.0 inches |

| Width | 38.25 inches | |

| Height | 40.75 inches | |

[1] - 15 U.S. quarts refill capacity with oil change and lube oil filter replacement. Actual engine oil capacity is slightly higher; high pressure oil pump reservoir and injector oil rails not drained during standard oil change procedure. Capacity may vary in Ford and International medium duty applications.

[2] - Horsepower and torque ratings in Ford Super Duty applications only; see additional output options in subsection below.

[3] - Ford Super Duty applications only; medium duty & E-Series options vary.

6.0 Powerstroke Engine Oil Viscosity Chart

Several engine viscosities are appropriate for the 6.0L Power Stroke diesel, with a SAE 15W-40 motor oil being preferred when the ambient temperature is above 30° F and a SAE 10W-30 engine oil being preferred between -10° F and 30° F. Note that the 15W-40 and 10W-30 viscosities have preferred ranges; if the "acceptable" temperature ranges are removed and only the "preferred" ranges are taken into consideration, the oil viscosity selection chart would appear as such:

| Temperature Range | Oil Viscosity | Remarks |

| > 30° F | SAE 15W-40 | [1],[2] |

| -10° F to 30° F | SAE 10W-30 | [1],[3] |

| < 30° F | SAE 5W-30 | [1],[3] |

| < 0° F | SAE 0W-30 | [1],[3] |

[1] - API CI-4 or CH-4 diesel motor oil

[2] -

SAE 15W-40 viscosity grade engine oil is required when towing in temperatures that exceed 50° F.

[3] - Recommend using engine block heater 2 to 3 hours before starting engine in temperatures below 0° F.

It is extremely important to select the correct engine oil viscosity grade for the anticipated ambient temperature range, even if this requires changing the engine oil before any such maintenance is required by the service interval. Operating in extremely cold climates also tends to increase the fuel dilution rate, thus more frequent service should be considered based on the ambient and driving conditions. The engine oil must also adhere to the API CI-4, CH-4, or equivalent standards.

Horsepower & Torque by Application

| Application | Horsepower (hp @ rpm) |

Torque (lb-ft @ rpm) |

| 2003 - 2004 Ford Super Duty [1] | 325 @ 3,300 | 560 @ 2,000 |

| 2005 - 2007 Ford Super Duty [1] | 325 @ 3,300 | 570 @ 2,000 |

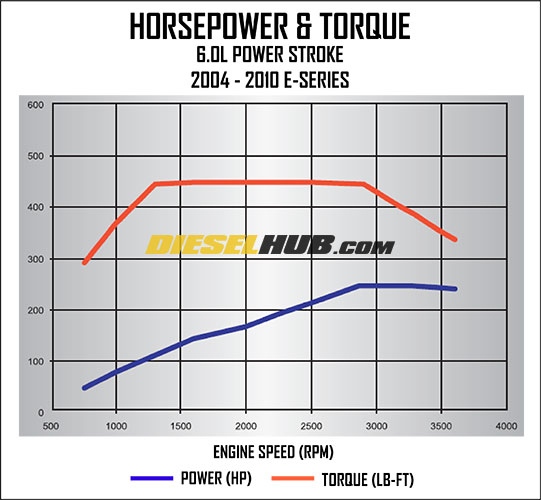

| 2004 - 2010 Ford E-350, E-450 Vans | 235 @ 3,150 | 440 @ 1,600 |

| 2003 - 2008 Ford F-650, F-750 [2] | 200 @ 2,600 | 520 @ 1,500 |

| 215 @ 2,600 | 540 @ 1,500 | |

| 230 @ 2,600 | 540 @ 1,500 | |

| 230 @ 2,600 | 620 @ 1,500 |

[1] - Includes F-250, F-350, F-450, F-550 pickup and chassis cab trucks, Ford Excursion

[2] - Multiple power and torque ratings simultaneously available for medium duty F-650, F-750 models

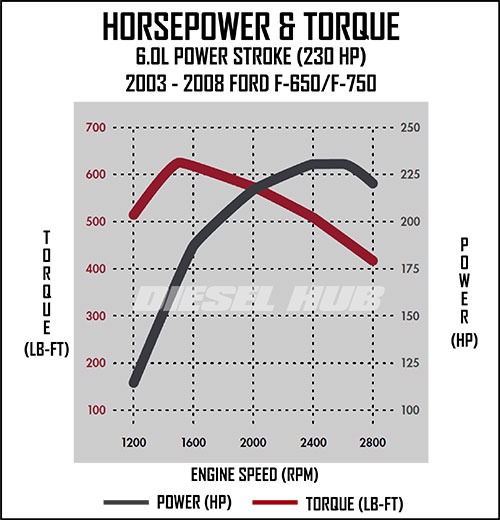

6.0 Power Stroke Horsepower & Torque Curves

325 horsepower, 560 lb-ft of torque

325 horsepower, 570 lb-ft of torque

235 horsepower, 440 lb-ft of torque

230 horsepower, 620 lb-ft option

Although commercial variations of the 6.0L Power Stroke reach peak torque at a lower engine speed (1,500 or 1,600 rpm), this engine is primarily known for its mid-range power and torque, which is useful in maintaining speed on steep grades. Note that the E-Series variation of this engine displays an extremely flat torque curve between 1,400 and 2,800 rpm, but the engine's calibration limits peak torque to 440 lb-ft; this is significantly lower than the pickup and chassis cab truck's 560 - 570 lb-ft.

Common 6.0 Powerstroke Engine Problems

Note that this is not a comprehensive list of 6.0L Power Stroke ailments; see common 6.0 Power Stroke problems for a more detailed version of this segment. Frequently reported failures of the following components and systems plagued early models of the 6.0L Power Stroke:

• Clogged EGR valve, clogged or leaking EGR cooler

• Clogged and/or failed engine oil cooler

• FICM failures

• High pressure oil pump (HPOP) failures, ICP sensor failures, problems related to the high pressure oil system

• Sticking unison ring or vanes in the variable geometry turbocharger (low power, poor engine responsiveness)

• Wire harness chaffing, open or shorted circuits on the engine wiring harness

• Head gasket failures

One could argue that the EGR system plagued the 6.0L Power Stroke and was responsible for many of the engine's problems. As the EGR valve collects soot, it can become mechanically stuck and cease to function. This can cause various conditions depending on the position that the valve becomes stuck in - when stuck in the closed position, for example, engine coolant is cooked in the EGR cooler, raising the coolant temperature and potentially causing cracks in the cooler itself. Disappearing engine coolant and/or contaminants found in the cooling system are signs of a failed EGR cooler. The higher operating temperatures are also a contributing factor in head gasket failures, although it is commonly accepted that the TTY head bolt design left much to be desired.

Faults originating in the high pressure oil system can, in part, be blamed on the location of the ICP sensor near the turbocharger in early model engines. This was corrected by moving the ICP sensor to the passenger side valve cover for the late 2004 redesign, which featured a magnitude of changes aimed at increasing the engine's reliability and reducing warranty claims.

While the variable geometry turbocharger offers excellent response and builds boost quickly, the moving mechanisms in the turbine housing are susceptible to collecting soot and mechanically seizing. The only remedy for such occurrences is to disassembly, clean, and reassemble the turbocharger (although most dealerships were more likely to replace the entire turbocharger assembly under warranty). A heavy coating of anti-seize lubricant seems to keep these components moving properly. Like the EGR valve sticking issues, the condition this would create would depend on the position in which the vanes are stuck, but ultimately resulted in either a low power condition or a low response condition.

As if the early fuel injection control module's (FICM) were not problematic enough, they would prove extremely sensitive to vehicle voltage and a failed alternator or low battery charge can destroy a FICM in seconds. Additionally, the engine wiring harness proved quite prone to chaffing and creating an open or shorted circuit that could prove difficult to find. In more rare cases, the wires could chafe inside of the wire loom leaving no visible indication that the harness was rubbing.

While the 6.0L Power Stroke has faced its fair share of criticism, these engines dominated the commercial and noncommercial truck segments in sales with plenty of vehicles powered by this engine platform remaining in service today. It is not uncommon to see 2003 to 2007 Super Duty's at commercial vehicle auctions with odometers in excess of 500,000 miles. Today, technicians are well equipped to isolate and even offer preventative solutions to many of the 6.0 liter's inherent problems.