The fabled 7.3L Power Stroke is a 4 stroke, turbocharged, V-8 diesel engine designed and manufactured by International Navistar for various Ford light and medium duty vehicle platforms, most notably of which is the Ford F-Series and later Super Duty pickup truck platforms. It is based on International's T444E (turbocharged, 444 CID, electronically controlled), sometimes also referred as the 7.3L DIT (direct injection, turbocharged).

The large displacement V-8 is well renowned in both consumer and commercial vehicle markets for its brazen reliability and longevity. It remains a popular engine platform today, despite being widely outperformed by modern engines employing superior technologies. The 7.3L Power Stroke, although sophisticated for its time, remains somewhat easy to diagnose and repair without the need for advanced diagnostic equipment and training.

Ford 7.3 Powerstroke History

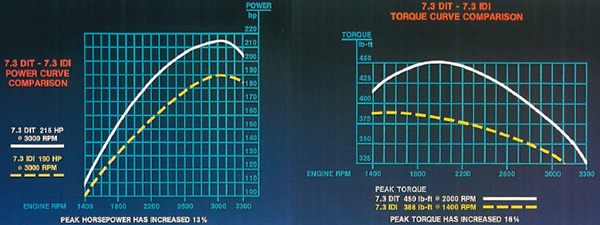

The 7.3L Power Stroke was introduced as a replacement for the 7.3L IDI. While the 7.3L IDI is regarded as a highly reliable engine platform, also designed and manufactured by International Navistar, it was severely lacking in performance and performance potential moving forward in what was becoming an extremely competitive segment. Dodge's 5.9L Cummins powered Ram was attracting significant attention after the 1994 model year redesign and GM's Detroit diesel was adopting electronic fuel metering controls to enhance efficiency. Ford and International, targeting separate but overlapping markets, required a new engine platform that could maintain the status quo.

Ford first offered the 7.3L Power Stroke midway into the 1994 model year as an engine option for F-250, F-350, and F-Super Duty (chassis cab) truck models. The launch was largely successful and the new Power Stroke V-8 became a popular choice in both the pickup and chassis cab truck markets. International's variation of the engine, the T444E, was enjoying equal success in the medium duty truck and bus segments. In 1994, the 7.3L Power Stroke was rated at a peak 210 horsepower and 425 lb-ft of torque. Meanwhile, International was offering the T444E in multiple power ratings ranging from 175 to 230 horsepower and 430 to 605 lb-ft of torque.

The 7.3L Power Stroke's popularity is evident in its production numbers, which greatly exceeded that of any competing automaker's diesel vehicle sales. By 1999, 1 million Power Stroke diesel equipped Ford F-Series had been delivered to dealerships across the United States. Demand soared following the introduction of the Super Duty truck platform and the 2 millionth 7.3L Power Stroke equipped Ford truck rolled off the assembly line in 2002.

A greater demand for fuel economy and significantly lower emissions would ultimately lead to the retirement of this engine platform by the end of the 2003 model year. While the 7.3L and 6.0L Power Stroke engines were available through the majority of the 2003 model year, the new 6.0L Power Stroke would be the only diesel option offered by Ford for 2004.

Engine Design

The 7.3L Power Stroke is a 90 degree, 8 cylinder vee configuration engine with a 4.11 inch cylinder bore and 4.18 inch stroke length, resulting in a bore-stroke ratio of a marginally undersquare 0.98. The parent bore (unlined) engine block is produced from cast iron, as are its cylinder heads. All early engines received forged steel connecting rods and aluminum pistons, while later engines (including some experimental production runs) utilized less desirable powdered metal connecting rods.

Lubrication & Cooling System

A crankshaft driven gerotor type low pressure oil pump is mounted behind the damper (harmonic balancer) against the front engine cover. In addition to keeping the engine lubricated, the pump is responsible for feeding the high pressure oil pump (see fuel system subsection below) mounted at the top of the engine. A transversely positioned lube oil cooler is mounted across the side of the engine block just beneath the driver side exhaust manifold. Coolant is pumped through this heat exchanger to help draw heat from the lube oil supply and prevent it from reaching excessive temperatures. Due to the engine's HEUI injection system, oil temperature control is an extremely important aspect of total engine cooling.

The cooling system itself is entirely traditional and features a mechanical, belt driven water pump mounted centrally at the front of the engine. A mechanical cooling fan is employed to maintain airflow across the radiator in extreme ambient temperatures or at high engine operating temperatures. While the prescribed thermostat opening temperature has changed over time and application, the current Motorcraft replacement thermostats have an opening temperature between 190 and 192 degrees Fahrenheit.

Fuel System

The 7.3L Power Stroke employs a hydraulic-over-electric unit injection system by which pressurized engine oil is used to intensify actual fuel injection pressure at the injector nozzle. A high pressure oil pump (HPOP) supplies high pressure engine oil through a dedicated circuit in each cylinder head where it is delivered to each individual fuel injector. The operating range of the high pressure circuit is between 500 and 2,700 psi, depending on operating conditions; higher engine demands requiring generating higher oil pressures for efficient engine operation and power production.

Fuel is also supplied to each injector through galleries cast into the cylinder head. 1994 to 1997 model year engines employ a camshaft driven, two stage mechanical fuel pump mounted in the engine valley while 1999 and later engines utilized a chassis mounted, inline electric fuel pump.

The fuel injectors mount through brass sleeves in the cylinder head, which are cooled by engine coolant flowing through the cylinder head. As the injectors have a constant supply of low pressure fuel and high pressure oil whenever the engine is running, they are actuated electronically by a large solenoid affixed to the top of the injector. For more specific information on HEUI injectors, see: how HEUI fuel injectors work.

Turbocharger

All 7.3L Power Stroke diesels have a single fixed geometry turbocharger mounted to the valley near the rear of the engine. 1999.5 (late 1999) and newer engines feature a wastegate and air-to-air intercooler. For all model years, the turbocharger was available with or without an exhaust backpressure valve (EBPV). The EBPV is a butterfly-type valve mounted at the outlet of the turbine housing (the downpipe attaches to the EBPV housing on applicable configurations). This device is designed to be closed via PCM activation when the engine is cold to provide a quicker warm-up cycle.

Emissions Equipment

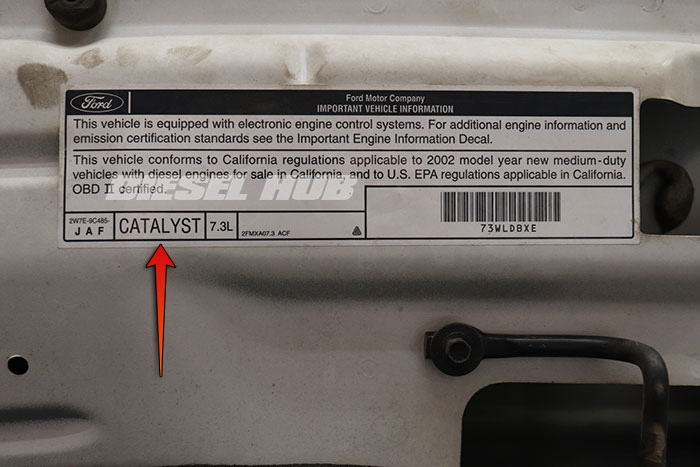

Most 7.3L Power Stroke engines do not have exhaust aftertreatment equipment. According to Ford's service literature, the only engine's requiring a diesel oxidation catalyst (DOC) were trucks equipped with manual transmissions (ZF 5 or 6 speed). In reality, there are many automatic trucks with factory equipped DOCs. While many believe this to be a Federal vs California emissions situation, there are many automatic transmission equipped trucks with Federal emissions packages (built for sale outside of CA) that were factory equipped with a DOC and we've been unable to verify this connection. All manual transmission equipped trucks powered by the 7.3 liter rolled off the assembly line with a DOC.

Transmission Options

1994 to 1997 model year trucks received the Ford E4OD four speed automatic transmission or ZF S5-47 five speed manual transmission (while rare, some 1994 model year vehicles may have received the ZF S5-42 manual transmission). The later 1999 to 2003 Super Duty trucks received the 4R100 four speed automatic transmission or ZF S6-650 six speed manual transmission. There were many transmission options made available for F-650 and F-750 medium duty trucks, including four, five, and six speed automatics and five, six, and seven speed manual transmissions.

7.3 Power Stroke Engine Specs

| Engine | 7.3L Power Stroke (International T444E, 7.3L DIT) | |

| Type & Configuration | 4 stroke diesel, 90° V8 | |

| Applications | 1994 - 1997 Ford F-250, F-350, F-Super Duty 1999 - 2003 Ford F-250, F-350, F-450, F-550 Super Duty 1995 - 1998 Econoline E-350 1999 - 2003 Econoline E-350, E-450 2003 Econoline E-550 2000 - 2003 Ford F-650, F-750 medium duty trucks |

|

| Advertised Displacement | 444 cubic inches, 7.3 liters | |

| Calculated Displacement | 443.65 cubic inches, 7.27 liters | |

| B10 Life | 200,000 miles (~320,000 km) | |

| B50 Life | 350,000 miles (~560,000 km) | |

| Bore | 4.11 in (104.4 mm) | |

| Stroke | 4.18 in (106.2 mm) | |

| Bore/Stroke Ratio | 0.98 (marginally undersquare) | |

| Compression Ratio | 17.5:1 | |

| Firing Order | 1-2-7-3-4-5-6-8 | |

| Cylinder Numbers |  Cylinders 1, 3, 5, 7 located on the passenger side bank; cylinders 2, 4, 6, 8 located on driver side bank |

|

| Engine Block Material | Cast iron | |

| Cylinder Head Material | Cast iron | |

| Injection System | Direct injection (DI) Hydraulic electronic unit injectors (HEUI) |

|

| Aspiration | Turbocharged, single fixed geometry turbo | |

| 1994 - 1997 model years | Garrett TP38, wastegated | |

| 1999 - 2003 model years | Garrett GTP38, wastegated, intercooled (air-to-air intercooler) | |

| Reciprocating Assembly | Forged steel connecting rods (1994 - 2000, some 2001) Powdered metal connector rods (some 2001, 2002 - 2003) [1] Aluminum pistons |

|

| Valvetrain | Overhead valve (OHV), 2 valves per cylinder (16 valve) Standard cam-in-block pushrod setup Hydraulic lifters with roller followers (no valve lash adjustments) Induction hardened steel camshaft |

|

| Cold Start Aid(s) | Traditional glow plug system, 1 glow plug per cylinder | |

| Engine Oil Capacity | 15.0 U.S. quarts with oil filter change [2] | |

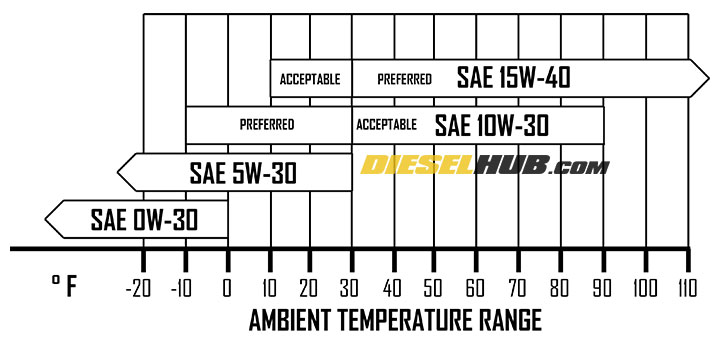

| Engine Oil Spec | See engine oil viscosity chart below | |

| Lube Oil Filter | Motorcraft FL-1995-A | |

| Fuel | #1 or #2 diesel fuel (includes winterized blends) Not evaluated for biodiesel or biodiesel blends |

|

| Fuel Filter | Motorcraft FD4595 (1994 - 1997 w/ mechanical fuel pump) Motorcraft DF4596 (1999 - 2003 w/ electric fuel pump) |

|

| Horsepower | 210 - 275 hp (see breakdown by model year in chart below) | |

| Torque | 425 - 525 lb-ft (see breakdown by model year in chart below) | |

| Idle Speed | ~ 675 rpm at operating temperature (+/- ), typical range 650 - 800 rpm [3] | |

| Governed Speed | Approximately 3,400 rpm (auto transmission max shift speeds will vary) | |

| Coupled Transmissions | Ford E4OD 4 speed auto, Ford 4R100 4 speed auto, ZF S5-42 5 speed manual, ZF S5-47 5 speed manual, ZF S6-650 6 speed manual | |

| Engine Weight | Approximately 920 lbs, dry | |

| Engine Dimensions | Length | ~ 34 inches |

| Width | ~ 32 inches | |

| Height | ~ 38 inches | |

[1] - Powdered metal connecting rods are found on engine serial numbers 1425747 to 1440712 and 1498319 and greater; all other engines have forged connecting rods

[2] - Original specification was 12 quarts with filter change; dipstick was re-calibrated for the 1995 model year to indicate full crankcase at 14 quarts (oil filter holds approximately 1 quart)

[3] -

Idle speed is electronically controlled and will vary with ambient temperature and engine oil temperature

Engine Oil Viscosity Chart

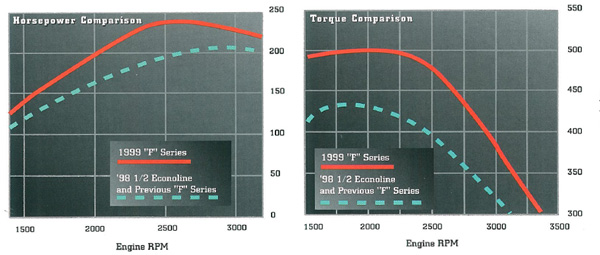

7.3 Power Stroke Horsepower & Torque Curves

Horsepower & Torque by Model Year

Note that the following horsepower and torque values are based on Ford's advertised ratings, for which there are some discrepancies. Actual ratings may vary slightly due to previous model year carryovers and other oddities. The actual horsepower rating for any 7.3L Power Stroke is listed on the identification tag affixed to the passenger side valve cover.

Ford F-Series & Super Duty

| Model Year | Horsepower (hp @ rpm) |

Torque (lb-ft @ rpm) |

|

| 1994 - 1995 | 210 @ 3,000 | 425 @ 2,000 | |

| 1996 | With CA emissions package: | 210 @ 3,000 | 425 @ 2,000 |

| With Federal emissions package: | 215 @ 3,000 | ||

| 1997 | 215 @ 3,000 | 425 @ 2,000 | |

| 1998 | No 1998 model year F-250 or F-350 | ||

| 1999 | 235 @ 2,700 | 500 @ 1,600 | |

| 2000 | 235 @ 2,600 | 500 @ 1,800 | |

| 2001 | Early 2001, automatic transmission: | 250 @ 2,600 | 505 @ 1,600 |

| Early 2001, manual transmission: | 235 @ 2,600 | 500 @ 1,800 | |

| Late 2001, automatic transmission: | 250 @ 2,600 |

505 @ 1,600 |

|

| Late 2001, manual transmission: | 275 @ 2,800 [4] | 520 @ 1,600 [4] | |

| 2002 | F-Series truck, automatic transmission: | 250 @ 2,600 |

505 @ 1,600 |

| F-Series truck, manual transmission: | 275 @ 2,800 | 520 @ 1,600 | |

| Excursion: | 250 @ 2,600 | 525 @ 1,600 | |

| 2003 | Automatic transmission: | 250 @ 2,600 | 525 @ 1,600 |

| Manual transmission: | 275 @ 2,800 | 520 @ 1,600 | |

[4] - Improved calibration for manual transmission equipped trucks became available late in 2001 model year

Ford E-Series (Econoline, Cutaway, RV Chassis)

| Model Year | Horsepower (hp @ rpm) |

Torque (lb-ft @ rpm) |

||||||

| 1995 | 210 @ 3,000 | 425 @ 2,000 | ||||||

| 1996 | Club Wagon: | 210 @ 3,000 | 425 @ 2,000 |

|||||

| RV & Cutaway: | 215 @ 3,000 | 425 @ 2,000 | ||||||

| 1997 - 1999 | 210 @ 3,000 | 425 @ 2,000 |

||||||

| 2000 - 2003 | 215 @ 2,600 | 425 @ 1,800 |

||||||

Ford F-650 & F-750 Medium Duty Trucks

The 7.3L Power Stroke V-8 was available in the F-650/F-750 medium duty platform beginning with the 2000 model year and ceasing after 2003 when the engine was replaced with the 6.0L Power Stroke. For all four model years, the Power Stroke was only available in a single power option advertised at 210 horsepower at 2,300 rpm and 520 lb-ft of torque at 1,500 rpm. The Caterpillar 7.2L I-6 and Cummins 5.9L ISB were offered concurrently in various power and torque output configurations during these years.

International T444E vs 7.3 Powerstroke

The International T444E and 7.3L Power Stroke are essentially identical with few differences and full parts interchangeability. T444E engines were commonly used in medium duty truck and bus applications manufactured by International-Navistar; these applications include platforms with a gross vehicle weight rating in excess of 60,000 pounds.

The most prevalent difference between the T444E and 7.3L Power Stroke is the PCM/ECM calibration, which controls the total rated output through fuel injector rates, timing, injector control pressure, and governed engine speed. While the most powerful 7.3L Power Stroke produced a peak 525 lb-ft and 250 horsepower, the highest output T444E produced a peak 620 lb-ft and 238 horsepower. The large differences in these figures is simply the result of different engine calibrations.

International and Ford also manufacture many of their own sensors for the T444E and 7.3L Power Stroke. While these sensors operate at the same ranges and accomplish the same tasks, you'll note that many parts, such as the ICP sensor, available through International parts dealers appear different than those available through Ford Motor Company. The accessory drive, turbocharger model, and water pump design may also differ between T444E and 7.3L Power Stroke engines depending on the model year and application.

International T444E Power & Torque Options

The International T444E has been produced in various power and torque configurations, including those listed in the chart below.

| Advertised Power | Horsepower (hp @ rpm) |

Torque (lb-ft @ rpm) |

Governed Speed |

| 175 horsepower | 184 @ 2,200 | 460 @ 1,400 | 2,600 rpm |

| 195 horsepower | 195 @ 2,300 | 520 @ 1,400 | 2,600 rpm |

| 210 horsepower | 215 @ 2,400 | 540 @ 1,500 | 2,600 rpm |

| 215 horsepower | 225 @ 2,200 | 560 @ 1,400 | 2,600 rpm |

| 230 horsepower | 238 @ 2,300 | 620 @ 1,400 | 2,600 rpm |

Available power options will vary by model year and application type.

Common 7.3 Power Stroke Engine Problems

Note - the following problems are listed in no particular order and this list has been limited to the most common failures not resulting from maintenance neglect or compounding problems.

Cracked Injector Sleeves (Cups)

Each fuel injector is mounted into a pressed-in brass sleeve within the cylinder head. The sleeve separates the lower half of the fuel injector from engine coolant flowing through the cylinder head passage, which prevents the fuel injectors from overheating during operation. These sleeves are largely prone to developing stress cracks and fractures, generally allowing fuel to contaminate the cooling system. If there are signs of diesel fuel in the engine coolant, a failed injector sleeve is highly likely to be the culprit.

UVCH, Injector Harness Connector Failures

This is a very common problem on 7.3L Power Stroke diesels and unfortunately it is often misdiagnosed as a faulty fuel injector. The valve cover gasket on a 7.3L Power Stroke has a connector formed into it that allows the engine wiring harness to connect to the injector/glow plug harness housed inside of the valve cover. It is typically referred to as the "under valve cover harness", or UVCH for short. This connector and its mate from the engine wiring harness are notorious for failing, generally due to oil and heat exposure. When a poor connection is present, one or more injectors on that bank can fail to operate. It is not uncommon for this condition to be intermittent, thus wiggling the connector while the engine is running is a common method used to isolate the problem; if the engine cuts out, stalls, or there is a misfire, that connection is poor.

Camshaft Position Sensor Failures

Frequent and repeated camshaft position sensor (CPS) failures were widely common on the 7.3L Power Stroke through the 90's and into the early 2000's. After several sensor changes, Ford's current replacement seems to be widely reliable. Today, if you're experiencing repeated CPS failures consider checking the CPS connector. In high mileage engines, it is also not uncommon for trigger wheel wear to cause a CPS signal problem, for which the only remedy is pull the engine and replace the trigger wheel (a quite extensive job).

IDM Failures

While we find nothing inherently wrong with the 7.3 liter's injector driver module (IDM), its mounting location is less than desirable. The IDM is positioned inside of the driver side fender, requiring the fender liner to be removed to access it. The problem with this location as that moisture can get into the module, causing it to corrode or even short out. As these devices generate heat during operation, there is an air vent cast into the case where moisture, even from humid air, can enter and wreck havoc.

Oil Cooler Leaks

Servicing the oil cooler on a 7.3L Power Stroke is not terribly expensive, but it can be a messy task. The oil cooler is sealed by four o-rings, two on either end, which keep the coolant and engine oil separated. As these o-rings age, they tend to become brittle, making them more susceptible to cracking. Internal leaks may result in engine oil and coolant mixing, while an external leak tends to start as a small drip before progressing into a larger leak.