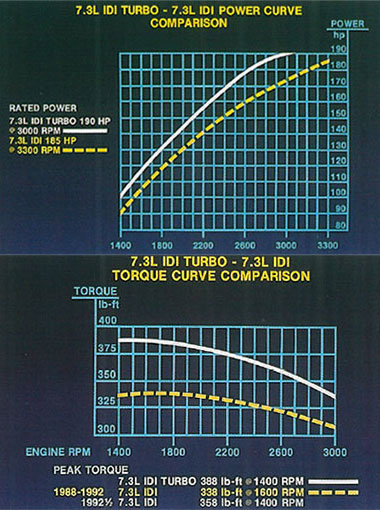

According to Ford Motor Company, the turbocharged model would maintain peak performance at elevations up to 10,000 feet above sea level. The 7.3L IDI is unlikely to win any races, but the engine's high compression ratio results in "snappy" throttle response and the overall design is capable of moving heavy loads while offering reasonable fuel economy. The most powerful version of the naturally aspirated 7.3L IDI in the Ford F-Series was rated at 185 horsepower and 358 lb-ft of torque, while the turbocharged version produced up to 190 horsepower and 388 lb-ft of torque. International offered the engine in several power ratings ranging from 130 horsepower to 170 horsepower in its medium duty trucks. The engine was also used in various industrial, construction, and agriculture applications in a range of power ratings.

The legacy of the 7.3L IDI is one of simplicity, reliability, and longevity. Properly maintained, this engine will stand the test of time. While the engine is lacking in the performance department by modern standards, it goes down in history as an honest engine that more than met the criteria of the times. The engine was ultimately replaced by the 7.3L DIT (Power Stroke) midway through the 1994 model year. Although the 7.3L IDI and 7.3L DIT share the same cylinder bore diameter and stroke length (and therefore total displacement), the design of these two engines differs vastly.

The 7.3L IDI diesel features a simple mechanical injection system, the heart of which is a Stanadyne DB2 rotary-style injection pump that feeds the mechanical pintle type fuel injectors. Fuel is fed to the injection pump by a camshaft driven mechanical fuel pump mounted to the engine block on the passenger side. This system is generally regarded as highly reliable and maintenance/repair costs are relatively low, although pump longevity has been negatively impacted by ULSD (ultra low sulfur diesel) fuels due to their lower lubricity. Religious use of a fuel additive to provide supplemental lubrication to the fuel system is advised and seems to offset most negative impacts of ULSD.

In the Ford F-Series, the 7.3L IDI was mated to a ZF 5 speed manual, C6 three speed automatic, or E4OD four speed automatic transmission. C6 variants are uncommon as the E4OD replaced it for the 1989 model year. Both the E4OD and ZF 5 speed are overdrive transmissions and offer greatly improved fuel economy and driveability at highway speeds, particularly since a 4.10 final drive ratio is common on 7.3L IDI equipped F-Series pickups and an overdrive gear keeps engine speeds reasonable.

7.3 IDI Engine Specs

Engine: |

7.3L IDI diesel |

||

Manufacturer: |

International Harvester, International Navistar |

||

Applications/Production Years: |

1988 - 1994 Ford F-250, F-350, F-Super Duty |

||

Displacement: |

444 CID (443.65 CID actual), 7.3 liters (7.27 liters actual) |

||

Configuration: |

90° V-8 |

||

Bore: |

4.11 inches (104.39 mm) |

||

Stroke: |

4.18 inches (106.20 mm) |

||

Bore/Stroke Ratio: |

0.98 (slightly undersquare) |

||

Compression Ratio: |

21.5 : 1 |

||

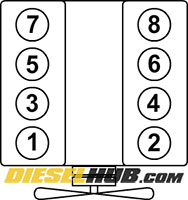

Firing Order: |

1 - 2 - 7 - 3 - 4 - 5 - 6 - 8 |

||

Cylinder Numbers: |

|

||

Engine Block Material: |

Cast iron |

||

Cylinder Head Material: |

Cast iron |

||

Fuel & Injection System: |

Injection type |

Indirect injection (IDI) |

|

Injection pump model |

Stanadyne DB2 distributor type mechanical pump |

||

Injector type |

Mechanical w/ pintle type nozzle |

||

Nozzle opening pressure |

Minimum 1,425 psi (~1,875 psi for a new injector) |

||

Dynamic timing |

8° BTDC +/- 2° |

||

Lift pump type |

Camshaft driven mechanical diaphragm |

||

Aspiration: |

Naturally aspirated & turbocharged variations; turbocharged engines available 1993 - 1994 model year and featured a non-intercooled Garrett T3 internally wastegated turbocharger with a 0.82 AR |

||

Reciprocating Assembly: |

Forged steel induction hardened crankshaft, forged steel I beam connecting rods, aluminum alloy pistons |

||

Valvetrain: |

Overhead valve, standard cam-in-block with hydraulic roller lifters, 2 valves per cylinder (16 valve) |

||

Valve Lash (Clearance): |

Hydraulic lifters, maintenance free |

||

Cold Start Aid(s): |

Solid state glow plug system, (1) glow plug per cylinder |

||

Thermostat Temperature: |

Begins to open @ 192° F, fully open @ 212° F |

||

Engine Oil Pressure: |

10 psi min @ 700 rpm, 40 - 70 psi @ max governed speed (no load) |

||

Engine Oil Capacity [1]: |

Ford F-Series |

10 quarts w/ filter change |

|

International trucks |

16 quarts w/ filter change |

||

Engine Oil Spec [2]: |

Ambient temp > 32° F |

SAE 30 |

|

Ambient temp > 0° F |

SAE 15W-40 |

||

Ambient temp < 32° F |

SAE 10W-30 |

||

Fuel: |

#2, #1, or winterized blended diesel fuel (biodiesel not advised) |

||

Horsepower: |

F-Series, naturally aspirated |

185 hp @ 3,000 rpm |

|

F-Series, turbocharged |

190 hp @ 3,000 rpm |

||

International trucks |

130 - 170 hp |

||

Torque: |

F-Series, naturally aspirated |

1988 - 1992 models |

338 lb-ft @ 1,400 rpm |

1992.5+ models |

358 lb-ft @ 1,400 rpm |

||

F-Series, turbocharged |

388 lb-ft @ 1,400 rpm |

||

International trucks |

272 lb-ft to 332 lb-ft |

||

Idle Speed: |

~ 675 rpm (low idle @ operating temp) |

||

Governed Speed [3]: |

No load |

3,250 - 3,470 rpm |

|

Full load |

~ 3,000 rpm |

||

Engine Weight: |

~ 995 lbs. dry |

||

Engine Dimensions: |

Length: |

30.0 in (not including fan assembly) |

|

Width: |

27.0 in |

||

Height: |

27.0 in (not including oil pan) |

||

[1] Engine oil capacity given for Ford F-Series and may differ in alternative applications. Always verify proper engine oil level using dipstick indicator marks.

[2] For more information on engine oil specifications and recommendations specific to the 7.3L IDI, see: 6.9L/7.3L maintenance schedule & service information and/or 7.3L IDI oil change guide.

[3] Actual governed speed may deviate from factory spec, and full load governed speed (fuel cutoff speed) may be slightly higher in Ford trucks than other applications. The A-130 variant found in International trucks, for example, has a no-load governed speed between 2,950 and 3,170 rpm, and a full-load governed speed of approximately 2,700 rpm. Max engine speed is governed by the injection pump.

6.9 IDI vs 7.3 IDI

While ultimately a derivative of the 6.9L IDI, the 7.3L IDI features many design differences, some of which limit the cross-compatibility of replacement parts. First and foremost, the 7.3L has a larger bore at 4.11 inches to the 6.9L's 4.00 inch bore diameter; the stroke length on both engines is identical at 4.18 inches. The 7.3L IDI also has an improved cylinder head design that includes a larger prechamber and offset glow plug locations. The cylinder head bolts on the 7.3L IDI are 1/2 inch diameter, compared to the 6.9L's 7/16 inch head bolts.

7.3 IDI Naturally Aspirated vs Turbocharged

To combat higher cylinder pressures, temperatures, and overall increased stress on engine components, the turbocharged variant of the 7.3L IDI features several notable improvements including:

- Cylinder head gasket received a larger/heavier fire ring.

- Piston wrist pin bore was increased from 1.1108 inches to 1.3086 inches (wrist pin diameter increased accordingly).

- New piston design that featured an anodized head and updated piston ring design.

Updated exhaust valve manufactured from a higher strength alloy. - Oil cooler heat exchanger increased from 24 fins per inch to 30 fins per inch for more effective heat removal.

- Heavier duty flywheel and engine damper (not interchangeable with the naturally aspirated version).

- Separate injection pump calibration and G code injector nozzles (naturally aspirated engines had E code injector nozzles).

Additionally, turbocharged engines had the glow plug controller relocated to the passenger side valve cover and the CDR moved to the driver side valve cover (on naturally aspirated engines, both are located at the rear of the intake manifold).

7.3 IDI Diesel Horsepower & Torque Curves

7.3L IDI and 7.3L IDI Turbo Horsepower/Torque Curves

Cavitation in the 7.3L IDI

Cavitation is likely the 7.3L IDI's greatest adversary. Cavitation is the phenomenon in which small vacuum pockets form on the outer wall of the cylinder. These pockets form due to harmonics created by the up-and-down motion of the piston in the cylinder in addition to the rocking motion the piston makes as it transverses, both of which occur very rapidly. The damage occurs when these vacuum pockets collapse, exerting small forces against the cylinder. Individually the forces are minute, but because they occur frequently and rapidly they physically erode the cylinder wall. Due to their high compression ratios diesel engines are generally at risk for cavitation related damage, however the 7.3L IDI is well known to be particularly susceptible.

This is combated by using an appropriate SCA/DCA (supplemental coolant additive/diesel coolant additive), which prevents these vacuum pockets from forming and attacking the cylinder wall. If the cooling system is not properly maintained, cavitation can eventually cause a hole to pierce through the cylinder wall. Another solution is the use of an ELC (extended life coolant), which are generally pre-charged with an SCA/DCA and many are maintenance-free for 300,000+ miles of service.