GM's highly anticipated reveal of the next generation Duramax diesel was disrupted when the engine's horsepower and torque figures were inadvertently published via GM's Powertrain division website; full details of the new engine platform were released shortly thereafter. Featuring peak 445 horsepower and 910 lb-ft torque output ratings, the 6.6L L5P Duramax is the most powerful Duramax diesel offered to date. Although sharing its displacement with previous Duramax engines, one could almost characteristically classify the L5P as a clean slate design. A completely revised high pressure fuel system, electronically controlled BorgWarner turbocharger, and significant structural improvements top the list of new engine features.

6.6 Duramax L5P Features

The 6.6L L5P Duramax was mated to the tried-and-true Allison 1000 six speed automatic transmission for 2017 to 2019 model years. For 2020, the GM-Allison 10L1000 ten speed automatic transmission became standard; although Allison transmissions was responsible for rigorously testing the transmission, it is a GM design and is assembled at GM's Toledo Transmission plant. The marginal separation from Allison was received equivocally, but the Allison branded transmission is widely popular amongst owners whom report smooth shifts and a sophisticated shift schedule that finds the right gear for the prevailing conditions.

L5P Duramax equipped trucks feature a unique, fully functional hood scoop integrated alongside a standard underhood air intake system. According to GM, approximately 60% of the engine's incoming air charged is provided through the hood scoop while 40% is furnished by the traditional intake system that draws ambient air though one of the front fenders. In addition to providing a cooler air intake charge, the hood scoop provides a "ram air" effect at cruising speeds, reducing turbocharger lag during quick spikes in engine load and improving overall engine performance while the vehicle is in motion. The hood scoop system includes an air-water separation chamber that GM claims keeps the incoming air charge dry regardless of weather conditions. At time of publishing, this intake system was a patent pending design.

6.6 Duramax L5P Specs

| Engine Family | 6.6L Duramax diesel (Duramax 6600) | |

| RPO Code | L5P | |

| VIN Code | Y (8th digit of VIN) | |

| Assembly Site | DMAX engine plant, Moraine, Ohio | |

| Applications/Production Years | 2017 - 2025 Chevrolet Silverado 2500HD, 3500HD 2017 - 2025 GMC Sierra 2500HD, 3500HD |

|

| Displacement | 6.599 liters (6.6 liters nominal), 402.62 CID (403 CID nominal) | |

| Configuration | 90 degree V-8 | |

| B10 Life | Not specified | |

| B50 Life | Not specified | |

| Bore | 4.055 inches (103.00 mm) | |

| Stroke | 3.897 inches (99.00 mm) | |

| Bore/Stroke Ratio | 1.04 (marginally oversquare) | |

| Compression Ratio | 16.0 : 1 | |

| Firing Order | 1-2-7-8-4-5-6-3 | |

| Cylinder Numbers |  Cylinders 1, 3, 5, and 7 are located on the passenger side bank Cylinders 2, 4, 6, and 8 are located on the driver side bank |

|

| Engine Block Material | Cast iron with induction hardened cylinder walls | |

| Cylinder Head Material | Cast aluminum alloy | |

| Injection System | Direct injection • High pressure common rail system • Denso GS4 Gen-III solenoid fuel injectors (up to 7 injection events per combustion sequence) • Denso HP4 injection pump • 29,000 psi max injection pressure |

|

| Aspiration | Turbocharged and intercooled | |

| Turbocharger | BorgWarner B2BV-70A VGT • Variable geometry turbine housing, electronically actuated • Non-wastegated • Air-to-air intercooler |

|

| Reciprocating Assembly | Cast aluminum alloy pistons with "re-melt" piston bowl rim Cast nodular iron main bearing caps Forged steel crankshaft Steel camshaft Powdered metal iron connecting rods |

|

| Valvetrain | Overhead valve (OHV), standard cam-in-block, mechanical roller lifters 4 valves per cylinder (32 valve) |

|

| Cold Start Aid(s) | Traditional glow plug system, 1 per cylinder, ceramic glow plugs | |

| Engine Oil Capacity | 10 quarts with oil filter change | |

| Engine Oil Spec | See viscosity chart at 6.6L Duramax L5P service guide | |

| Lube Oil Filter Part Number | ACDelco PF2232 | |

| Fuel | Ultra low sulfur diesel (ULSD) or max B20 biodiesel blend | |

| Fuel Filter Part Number | 2017 - 2019 models | GM TP1015 (fuel filter element) ACDelco TP1014 (fuel-water separator assembly) |

| 2020+ models | GM TP1015 (fuel filter element) GM TP1023(fuel-water separator assembly) |

|

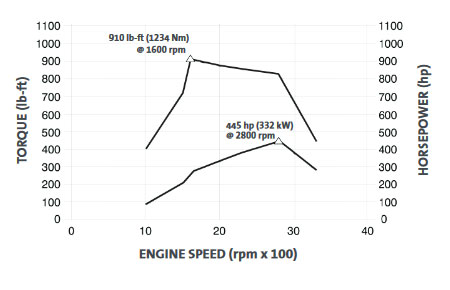

| Horsepower | 2017 - 2023 models | 445 hp @ 2,800 rpm |

| 2024+ models | 470 hp @ 2,800 rpm | |

| Torque | 2017 -2023 models | 910 lb-ft @ 1,600 rpm |

| 2024+ models | 975 lb-ft @ 1,600 rpm | |

| Idle Speed | Engine idle speed will vary with conditions that include electrical demand, regeneration status, and engine temperature; idle speed may be as low as 600 rpm. | |

| Governed Speed | 3,450 rpm (electronically governed maximum run speed) 4,800 rpm (electronically governed maximum engine braking speed) |

|

| Emissions Equipment | Selective catalytic reduction (SCR, requires diesel exhaust fluid), diesel particulate filter (DPF), diesel oxidation catalyst (DOC), exhaust gas recirculation (EGR) w/ intake throttle | |

| Coupled Transmissions | Allison 1000 six speed automatic, GM-Allison 10L1000 10 speed automatic (standard 2020+) | |

| Engine Weight | Approx. 835 lbs | |

| Engine Dimensions | Length | 31.8 inches |

| Width | 35.4 inches | |

| Height | 39.1 inches | |

6.6 Duramax L5P Horsepower & Torque Curves

6.6 Duramax L5P Changes, Upgrades, & Improvements

Although the displacement of the Duramax diesel remains unchanged, it represents a distant relative of past generations of the Duramax 6600 engine family. The electronic and structural design features of the L5P are far more sophisticated and robust than previous engine models. The following list of changes, improvements, and revisions contribute the L5P's increase in horsepower, torque, and structural integrity.

Engine Block, Rotating/Reciprocating Assembly

- Entirely new engine block casting featuring induction hardened cylinder walls and 5 nodular cast iron cross-bolted main bearing caps.

- More robust, larger diameter crankshaft.

- Increased connecting rod journal size with larger bearing surface area.

- Fractured cap forged and sintered powdered metal connecting rods.

- Cast aluminum "re-melted" pistons; the rim of the piston crown is heat treated after being cast in order to reduce grain size and create a more consistent grain structure to maximize strength.

- Revised camshaft design with enhanced cam lobe profiles.

- Two piece oil pan. The cast aluminum upper portion of the oil pan acts as an engine block girdle for improved strength and rigidity while the laminated steel lower portion aids in suppressing noise.

Turbocharger & Fuel System Improvements

- Electronically actuated BorgWarner variable geometry turbocharger producing peak boost pressure of 28 psi (manifold gauge pressure). The newly adopted turbocharger is said to provide more effective and more efficient exhaust braking through an enhanced VGT vane control system.

- Denso HP4 injection pump replaces the Bosch CP4 found on previous generations. Bosch CP4 injection pumps have been the source of reliability issues across multiple vehicle manufacturers.

- Denso electronically actuated solenoid-type fuel injectors permitting up to 7 injection events per combustion sequence.

- New air intake system featuring a fully functionally hood scoop.

- Introduction of a fuel lift pump to supply fuel to the high pressure injection pump (as opposed to relying on vacuum from the injection pump to draw fuel from the tank, as in previous generations).

Engine Oil & Cooling System Improvements

- Increased engine oil flowrate with piston cooling jets that flow 50% more oil than the 6.6L Duramax LML.

- Revised oil passages include a dedicated turbocharger oil supply circuit for improved lubrication and turbocharger cooling.

- High capacity engine oil cooler providing up to 50% greater engine oil cooling efficiency than the design found on the 6.6L Duramax LML.

- Increased engine coolant flow rate for more efficient engine cooling under severe conditions.

Cylinder Head & Glow Plug System Improvements

- New cylinder head casting with enhanced airflow and efficiency. Features layered coolant passages for greater rigidity and overall cylinder head strength.

- Improved ceramic glow plugs designed to reduce glow plug preheat cycle times. A new glow plug control system utilizes a temperature compensation attribute that can adjust current flow to each individual glow plug to maintain consistent cylinder-to-cylinder temperatures during cold starts.

2024 Duramax Diesel

General Motors announced a revised, more powerful version of the 6.6L Duramax diesel for the updated 2024 model year GMC Sierra and Chevrolet Silverado HD. The new engine, mated to the 10L1000 10 speed automatic transmission, produces a peak 470 horsepower and 975 lb-ft of torque; an increase of 25 horsepower and 65 lb-ft of torque versus the 2017 to 2023 model year engine. Additionally, GM claims that the revised Duramax offers up to 25% more torque at low engine speeds.