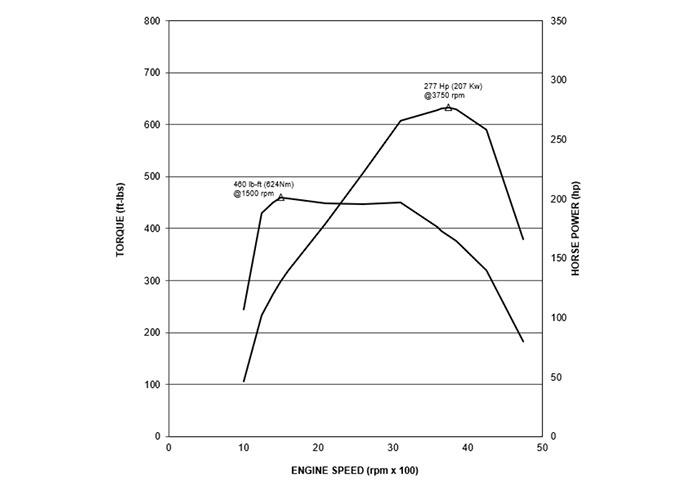

While General Motors was the last to deliver a diesel option to their series of half-ton pickup trucks, they did so in style with a class exclusive inline engine. First available in the 2020 Chevrolet Silverado and GMC Sierra 1500, the 3 liter 6 cylinder produced a peak 277 horsepower and 460 lb-ft while earning EPA rated fuel economy figures as great as 33 mpg on the highway for two wheel drive configurations and 29 mpg for four wheel drive models. The engine's closest competitor is the 3.0L EcoDiesel powered Ram 1500; Ford retired the F-150's 3.0L Power Stroke diesel following the 2021 model year.

3.0 Duramax Applications

LM2 Duramax

The first 3.0L Duramax diesels, RPO code LM2, are found in the 2020 model year Chevrolet Silverado 1500 and GMC Sierra 1500. GM's flagship truck platforms were likely the test pilot for the new engine, which became available in the Chevy Tahoe, GMC Yukon, Chevy Suburban, and Cadillac Escalade for the 2021 model year. All LM2 engines are advertised at 277 peak horsepower and 460 lb-ft peak torque, although some internally published data put early estimates at 282 horsepower and 450 lb-ft of torque.

All 3.0L Duramax engines are paired with the GM 10L80 ten speed automatic transmission. This transmission platform is unique in that it is the result of a collaboration between General Motors and Ford Motor Company, in which parts commonality was a major objective. Although the calibrations between the Ford and GM variations are quite different, most of the transmission's mechanical parts are interchangeable. The 10L80 offers a low 4.7 to 1 first gear and reasonably high 0.64 to 1 final overdrive ratio; the small steps between gear shifts help maximize the engine's efficiency by maintaining ideal engine speeds to match driving conditions.

LZ0 Duramax

The 3.0L Duramax received a significant update for the 2023 model year, increasing peak power to 305 horsepower and peak torque to 495 lb-ft. This translates to a 28 horsepower increase (10%) in peak engine power and a 35 ft-lb increase in peak rated torque (7.6%). For 2023 and 2024, the LZ0 was only available in GMC Sierra 1500 and Chevrolet Silverado 1500 truck models, but GM began using the more powerful engine option in its fullsize SUVs for 2025.

3.0 Duramax Design Features

Engine Block & Cylinder Heads

The foundation of the 3.0L Duramax is a cast aluminum engine block with pressed in iron cylinder liners. The aluminum engine block achieves significant weight savings while the iron cylinder liners ensure robust wear protection. Featuring an engine bore of 3.3 inches and a stroke of 3.54 inches, the configuration is undersquare (0.93 bore-stroke ratio) with a resulting displacement of 182.6 cubic inches.

A cast aluminum cylinder head is utilized on the 3.0L Duramax, again attributing to significant weight savings when compared to a cast iron design. The engine features a dual overhead camshaft design with independent intake valve and exhaust valve camshafts affixed within the cylinder head. Camshaft timing is achieved by a standard chain-and-sprocket system.

Turbocharger & Air Management

The 3.0L Duramax employs a Garrett variable geometry, ball bearing turbocharger packaged closely with the exhaust manifold to retain exhaust gas energy and maximize responsiveness. Vane position is electronically controlled via a turbo mounted actuator while the center housing is water cooled to reduce heat transfer to the compressor housing and reduce the lube oil's exposure to heat in and around the bearings.

The turbocharger peaks at nearly 43 psia, or approximately 28 psi gauge pressure (boost) at sea level. A water-to-air intercooler allows the compressed air charge to be cooled via the engine cooling system. Resonators on the compressor inlet and outlet are employed to reduce engine noise.

An electronically actuated variable intake manifold effectively shortens and lengthens intake runners via flap valves to perpetually optimize airflow based on operating conditions. While this technique does not necessarily have a major role in overall power development, it significantly contributes to providing a broad torque curve and general engine responsiveness.

Fuel System

The 3.0L Duramax features a high pressure common rail injection system capable of fuel pressures in excess of 36,000 psi (36,260 psi, 2,500 bar). A Denso HP5 injection pump is utilized in conjunction with Denso solenoid actuated fuel injectors. This combination allows for up to 10 injection events per combustion cycle under compatible operating conditions. Like other Duramax engines, the fuel injection pump is chain driven. The HP5 injection pump is a twin cylinder, vee configuration similar to that of the Bosch CP4. An in-tank electric fuel lift pump supplies fuel to the injection pump.

Cooling System

3.0L Duramax engines utilize a unique, highly complex active thermal management system. The engine coolant control valve, an assembly of 3 independently operated electrically actuated valves, manages engine coolant distribution through the engine block, cylinder head, heater core, transmission cooler, and engine oil cooler. The primary goal of the system is to distribute engine coolant where and when it is needed in order to provide rapid engine warm-up and maintain combustion chamber temperatures (note that combustion efficiency is closely related to operating temperature). To protect the cooling system from overheating, coolant flow through the EGR cooler is continuous.

To facilitate the operation of this system, 7 engine coolant temperature sensors are strategically mounted throughout the system. While a standard engine driven water pump is employed for primary engine cooling needs, a variable speed electric water pump supplies coolant through the charge-air-cooler circuit. Additionally, a second electric water pump is used in low ambient temperatures (< 59° F) to keep hot engine coolant circulating through the heater core during start-stop operation. The sole purpose of this device is to maintain cabin heater functions during cold weather operation when the engine is stopped; function of this electric water pump is disabled while the engine is running.

Emissions System

3.0L Duramax engines employ a close coupled exhaust aftertreatment network in addition to a cooled exhaust gas recirculation system. The exhaust aftertreatment system consists of a diesel oxidation catalyst, diesel particulate filter, and selective catalytic reduction catalyst requiring the introduction of diesel exhaust fluid into the exhaust gas stream. The compact system packages the aftertreatment equipment into a single unit (SCR on filter or SCRoF) on the passenger side of the engine, accessible through the engine compartment. Since the DPF is mounted in close proximity to the turbocharger outlet, exhaust heat is retained and aids in more efficient passive and active regeneration cycles.

3.0 Duramax Engine Specs

| Engine | 3.0L Duramax diesel | |

| GM RPO Code | LM2, LZ0 | |

| Vin Code (8th digit) | T (LM2), 8 (LZ0) | |

| Assembly Location | Flint Engine Plant, Flint, Michigan | |

| Applications | LM2 | 2020 - 2022 Chevrolet Silverado 1500 2020 - 2022 GMC Sierra 1500 2021 - 2024 Cadillac Escalade 2021 - 2024 Chevrolet Tahoe 2021 - 2024 Chevrolet Suburban 2021 - 2024 GMC Yukon |

| LZ0 | 2023 - 2025 Chevrolet Silverado 1500 2023 - 2025 GMC Sierra 1500 2025 Chevrolet Suburban 2025 GMC Yukon |

|

| Configuration | Inline 6 (I-6) | |

| Type | 4 stroke diesel, direct injection | |

| Advertised Displacement | 3.0 liters, 183 cubic inches | |

| Calculated Displacement | 2.99 liters, 182.49 cubic inches | |

| Bore | 3.307 inches (84.0 mm) | |

| Stroke | 3.543 inches (90.0 mm) | |

| Bore/Stroke Ratio | 0.93 (undersquare) | |

| Firing Order | 1-5-3-6-2-4 | |

| Cylinder Numbers |  |

|

| Engine Block Material | Cast aluminum with iron cylinder liners | |

| Cylinder Head Material | Aluminum alloy | |

| Compression Ratio | LM2 | 15.0:1 |

| LZ0 | 15.2:1 | |

| Injection System | Direct injection Denso high pressure common rail, 36,260 psi (2,500 bar) max injection pressure Chain driven, twin piston Denso HP5 high pressure injection pump Solenoid-type fuel injectors with 9 hole nozzles Up to 10 injection events per combustion cycle |

|

| Aspiration | Turbocharged, intercooled Garrett ball bearing, liquid cooled variable geometry turbocharger (VGT) Water-to-air charge air cooler Integrated exhaust brake 42.8 psia peak manifold pressure [1] |

|

| Valvetrain | Dual overhead camshafts (DOHC), chain driven 4 valves per cylinder (24 valve) Maintenance-free finger followers with hydraulic lash adjusters 1.12 inch (28.35 mm) intake valves 0.97 inch (24.55 mm) exhaust valves Variable flow intake manifold |

|

| Reciprocating Assembly | Hypereutectic cast aluminum pistons (LM2 only) Steel pistons (LZ0 only) Forged steel crankshaft Steel camshafts Forged steel connecting rods Nodular iron main bearing caps |

|

| Starting Aids | Ceramic 'fast-start' glow plugs, 1 per cylinder | |

| Fuel | Ultra-low sulfur diesel, maximum B20 biodiesel blend | |

| Fuel Filter | ACDelco TP1015 | |

| Lubrication | Continuous variable displacement oil pump (belt driven, rear of crankshaft) | |

| Engine Oil Capacity | 7.0 quarts with filter change | |

| Engine Oil Spec | SAE 0W-20 DexosD diesel engine oil | |

| Engine Oil Filter | ACDelco PF66 (standard) ACDelco UPF66R (Ultraguard Gold) |

|

| Horsepower | LM2 | 277 hp @ 3,750 rpm |

| LZ0 | 305 hp @ 3,750 rpm | |

| Torque | LM2 | 460 lb-ft @ 1,500 rpm |

| LZ0 | 495 lb-ft @ 2,750 rpm | |

| Max Engine Speed | 5,000 rpm (electronically governed) | |

| Fuel Economy | See full chart in subsection below | |

| Engine Dimensions | Length | 35.75 inches (908 mm) |

| Width | 35.98 inches (914 mm) | |

| Height | 35.55 inches (903 mm) | |

| Engine Weight | 467 lbs | |

[1] - 42.8 psi absolute pressure; converts to approximately 28 psi gauge pressure at sea level

Horsepower & Torque Curves

3.0 Duramax Fuel Economy

All listed fuel economy ratings are based on the highest available for that model and drivetrain configuration; fuel mileage ratings may vary based on optional equipment packages. EPA certified fuel economy ratings for all listed vehicles were retrieved from fueleconomy.gov and are displayed in the format city mpg/highway mpg/combined mpg.

Chevrolet Silverado & GMC Sierra

| Model Year | MPG 4x2 Models |

MPG 4x4 Models |

| 2020 | 23/33/27 | 23/29/25 |

| 2021 | 23/33/27 | 22/26/24 |

| 2022 | 23/31/26 | 22/26/24 |

| 2023 | 24/29/26 | 22/27/24 |

| 2024 | 24/29/26 | 22/27/24 |

| 2025 | 23/29/26 | 22/25/23 |

Chevrolet Tahoe & GMC Yukon

| Model Year | MPG 4x2 Models |

MPG 4x4 Models |

| 2021 | 21/28/24 | 20/26/22 |

| 2022 | 21/28/24 | 20/26/22 |

| 2023 | 21/28/24 | 20/26/22 |

| 2024 | 21/28/24 | 20/26/22 |

| 2025 | TBA | TBA |

3.0 Duramax LZ0 Updates & Revisions

The LZ0 has undergone significant changes to reliably deliver greater peak horsepower and torque. These changes, listed in no particular order of importance, include:

- New steel piston design with stepped bowl geometry, compression ratio increased to 15.2 to 1

- Thicker cylinder head gasket design

- New fuel injector design with revised spray pattern optimized for new piston bowl geometry

- Thicker cylinder block inserts (sleeves)

- Revised turbocharger compressor geometry

- New water pump with increased impeller size, greater coolant flowrate capacity

- Revised cooling system control valve and coolant circuit flow strategy

- Revised glow plug activation protocol, higher glow plug supply voltage

- Suggested oil pump belt life increased to 200,000 miles [2]

- DOC inlet positioned closer to turbocharger turbine outlet to improve efficiency, reach operating temperature quicker

- New cylinder head with longer intake valves

- Second DEF injector added to aftertreatment system

[2] - Oil pump is located at the rear of the engine and requires removal of the transmission to access. This repair has thus been a sore subject for 3.0L Duramax owners as although the part is relatively inexpensive (<$30), customers incur extremely large labor charges ( > $1,000) and additional charges on one-time-use parts removed in the process.