Applicable Models:

2007.5 - 2010 Dodge Ram 2500, 3500, 4500, 5500

2011 - 2024 Ram Trucks Ram 2500, 3500, 4500, 5500

Applicable Engine(s):

6.7L Cummins turbodiesel I-6

Fuel Filter Service Intervals:

15,000 miles (24,000 km)/12 months

6.7 Cummins Fuel Filter Information

For all 6.7L Cummins turbodiesels, the primary fuel filter, fuel-water separator unit is mounted to the driver side of the engine. All 2007 to 2012 model years rely solely on this filtration assembly, while 2013 and newer trucks employ an auxiliary filter mounted on the frame rail between the fuel tank(s) and engine. Cummins requires that the fuel filter(s) be replaced at 15,000 mile intervals, every 12 months, or promptly after a "fuel filter service required" or "water in fuel" message is presented in the instrument cluster display.

Filter replacement is vital to the health and protection of the 6.7L Cummins' fuel system. Note that 2019 and 2020 model year vehicles that employ the Bosch CP4 injection pump should inspect the fuel filters/water separator for metal remnants that could indicate a failing pump (FCA has recalled this pump and is reverting to the CP3, additional information is available here: Ram CP4 Recall). We also recommend draining the fuel filter housings into clean, clear containers so that the fuel can be inspected for contamination.

Fuel Filter & Associated Part Numbers

Filter Micron Ratings & NanoNet Filters

The original fuel filter for 2010 to 2012 model year engines (Fleetguard FS43255, MOPAR 68065608AB) is a 5 micron filter. Cummins would later introduce their "NanoNet" filter line, which features a 5 micron outer filter element and a 3 micron inner filter element. While specified for later model years, the NanoNet filters (Fleetguard FS53000, MOPAR 68157291AA) are backwards compatible and will fit 2010 to 2012 model year filter housings. Due to the lower micron rating, we highly recommend the NanoNet filters for all 2010 and newer engine models.

For those whom may be unaware, Fleetguard is Cummins' filtration product line; Fleetguard is to Cummins as MOPAR is to Dodge, Chrysler, Ram, Jeep, ACDelco is to General Motors, and Motorcraft is to Ford Motor Company. While there is nothing inherently wrong with the MOPAR branded fuel filters, cutting out the middle man and sourcing the Fleetguard filters from Cummins is often more cost effective. Many, if not most of the MOPAR branded parts for the 5.9L/6.7L turbodiesel are repackaged Cummins parts with a premium price. We tend to see more reasonable pricing straight from Cummins, the source supplier.

6.7 Cummins Fuel Filter Part Numbers

| Part Description | Part Number(s) | Remarks | |

| Fuel filter (engine) |

2007 - 2009 | MOPAR 68061634AA Fleetguard FS43258 |

--- |

| 2010 - 2012 | MOPAR 68065608AB Fleetguard FS43255 |

[1] | |

| 2010 - 2023 | MOPAR 68157291AA Fleetguard FS53000 |

||

| Fuel filter (chassis) |

2007 - 2012 | N/A | [2] |

| 2013 - 2018 | MOPAR 68197867AB | --- | |

| 2019 - 2023 | MOPAR 68436631AA | ||

[1] - Recommend Fleetguard FS53000 or MOPAR 68157291AA NanoNet fuel filter for all 2010+ applications. NanoNet filter media features a 5 micron outer filter element and a 3 micron inner filter element. MOPAR 68065608AB and Fleetguard FS43255 feature a 5 micron filter element; the NanoNet fuel filters are an upgrade for 2010 to 2012 model year vehicles.

[2] - 2007 to 2012 model year engines only utilize an engine mounted fuel filter, fuel-water separator system; there is no chassis mounted filter.

6.7 Cummins Fuel Filter Housings & Related

| Part Description | Part Number(s) | Remarks | |

| Fuel filter housing (engine) |

2007 - 2009 | MOPAR 68061633AA Fleetguard FS43257 |

[3] |

| 2010 - 2012 | MOPAR 68065609AC | ||

| 2013 - 2018 | MOPAR 68157290AB | ||

| 2019 - 2023 | MOPAR 68391351AA | ||

| Fuel filter housing (chassis) |

2007 - 2012 | N/A | [4] |

| 2013 - 2018 | MOPAR 68268285AC | [3] | |

| 2019 - 2023 | MOPAR 68358393AA | ||

| Fuel filter housing cap/lid (engine) |

2007 - 2009 | N/A | [5] |

| 2010 - 2023 | MOPAR 68065612AA | --- | |

| Fuel filter housing cap/lid (chassis) |

2007 - 2012 | N/A | [4] |

| 2013 - 2018 | N/A | [5] | |

| 2019 - 2023 | MOPAR 68436815AA | --- | |

| Fuel filter housing drain valve (engine) |

2007 - 2009 | N/A | [5] |

| 2010 - 2023 | MOPAR 68065611AA | --- | |

| Fuel filter housing drain valve (chassis) |

2007 - 2012 | N/A | [4] |

| 2013 - 2018 | MOPAR 68197868AB | [6] | |

| 2019 - 2023 | MOPAR 68436628AA | --- | |

| Water-in-fuel sensor (engine) |

2007 - 2023 | MOPAR 68065610AA | --- |

[3] - Complete fuel filter housing assembly, includes new fuel filter; replace if cracked or damaged.

[4] - 2007 to 2012 model year engines only utilize an engine mounted fuel filter, fuel-water separator system; there is no chassis mounted filter.

[5] - Not applicable, canister style fuel filter or other assembly type.

[6] - Filter drain valve/water-in-fuel sensor assembly.

Tools & Misc Parts

| Part Description | Part Number(s) | Remarks |

| Fuel filter cap socket | Lisle 13290 | [7] |

| Fuel-water separator drain hose kit | RT-360101 | [8] |

| Fuel additives | Amsoil All-in-One diesel fuel additive Amsoil Injector Clean + Cetane Boost Archoil AR6500 diesel treatment |

[9] |

[7] - A standard length 28 mm socket can be used in lieu of this tool, but the low profile design of the dedicated fuel filter socket is easier to work with in the congested area near the engine mounted fuel filter housing.

[8] - Includes brass hose fitting and 30 inches of chemical tubing to drain the engine mounted fuel-water separator.

[9] - We highly recommend a supplemental diesel fuel additive for all 6.7L Cummins turbodiesels; improved fuel lubricity will help extend the life of the fuel system.

Fuel-Water Separator Drain Hose

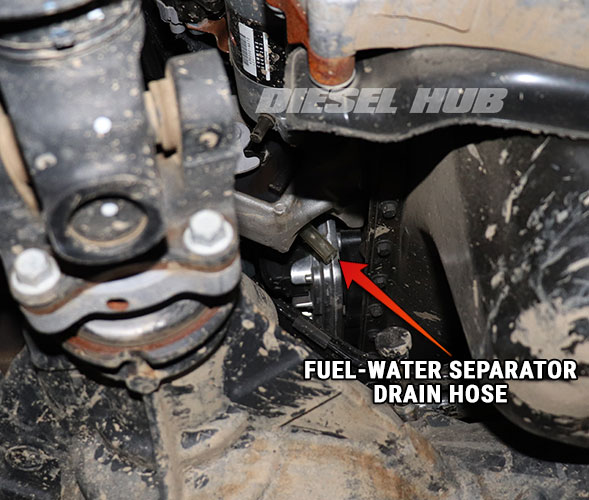

The fuel-water separator and primary fuel filter housing is mounted to the driver side of the engine. An integral drain valve mounted to the side of the housing drains the bowl through a hose protruding to the side of the engine oil pan flange. While the drain hose is readily accessible, there's little space to fit, let alone balance a container to catch fuel. The drain hose location can be seen pictured in figure 1 below. Note that on a four wheel drive vehicle, the hose is positioned above the front differential housing.

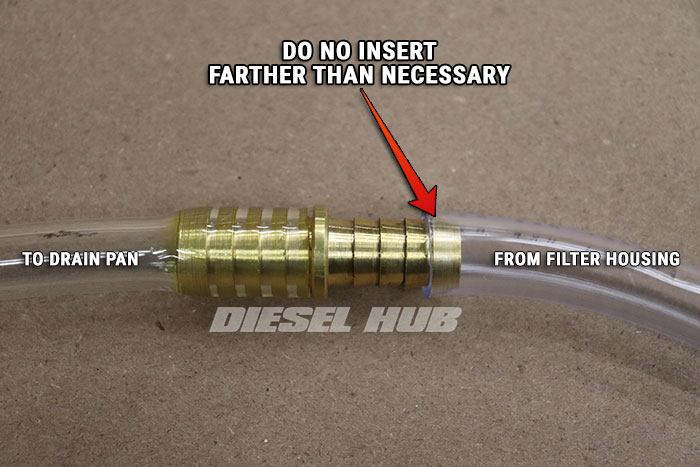

The solution is to effectively lengthen the hose so that the fuel-water separator and fuel filter housing can be drained without spilling diesel fuel and making an oily mess. A 1/2 inch hose mender (coupling) and section of clear chemical tubing work excellent in extending the drain hose into a suitable container. Figure 2 below is our example, an inexpensive setup that we sell in the Diesel Hub Store. Note that these materials should be widely available at your local hardware store.

It is important to note that you do NOT want to completely insert any barbed fitting into the filter housing drain hose, as the fitting may become stuck. To prevent the hose from becoming stuck and creating a permanent connection, only insert the barbed fitting as much as necessary (see figure 3). Since there is no pressure on this connection, it just needs to hold in place while the fuel bowl drains. By only inserting to or slightly past the first barb, it can easily be removed.

Priming the Fuel System on a 6.7 Cummins

Never prefill a fuel filter or filter housing with diesel fuel. The 6.7L Cummins turbodiesel employs an electric lift pump, thus priming the system is as simple as cycling the ignition to the "ON" or "RUN" position repeatedly. When the ignition is switched to the "RUN" position (do not start or crank), the electric lift pump will power on and begin cycling fuel through the system. This is an effective means of bleeding air from the fuel supply, priming the fuel system, and checking for leaks before actually starting or cranking the engine.

Simply turn the ignition switch to the "RUN" position and listen for the fuel pump; it will produce a whirling or whistling noise while it is running. When the fuel pump powers down (typically 10 to 15 seconds), return the ignition switch to the "OFF" position and repeat 10 to 12 times to ensure all air is removed from the system. On vehicles equipped with a push button ignition (i.e. no key switch), pressing the ignition button without placing your foot on the brake pedal will allow you to cycle through the "RUN" sequence without cranking or starting the engine.

If the engine stalls, sputters, or runs rough, the key was not cycled enough times to fully bleed the fuel system. Because injection pumps and injectors wear rapidly in the absence of fuel, we recommend cycling the ignition system a minimum of 10 times before attempting to start the engine after the fuel filters are replaced.

As applicable, always prime the fuel system after replacing each individual fuel filter. If the chassis mounted filter is replaced first, prime the fuel system before replacing the engine mounted filter. Priming the system in between each filter change serves two purposes; first and foremost, it primes the filter housing that was just serviced, reducing the amount of air in the system and hopefully reducing the effort required to prime the entire system after the second filter is replaced. Additionally, this allows any contaminants that may have been introduced to the open fuel system to be captured in the subsequent fuel filter before it is replaced.

How to Replace the Fuel Filters on a 6.7 Cummins Diesel

Note the following procedures were performed on a 2020 model year engine; there may be slight differences between generations. 2007 - 2012 model year engines, for example, do not feature a chassis mounted fuel filter.

Click any thumbnail to view fullsize, detailed image

• Fuel filter service should be performed every 15,000 miles, 12 months, or as instructed by the instrument cluster display (whichever of these circumstances that should come first).

• If a "water in fuel" or "fuel filter service required" message is prompted before nearing the 15,000 mile/12 month criteria, inspect the fuel drained from the filter housing(s) for contamination; while some water in the fuel is normal, excessive water strips diesel of its lubricity and contributes to increased wear.

• Locate the chassis mounted fuel filter housing near the front of the fuel tank and over a portion of the driveshaft.

• Attach a section of 5/16 inch fuel hose to the drain valve nipple at the bottom of the fuel filter housing cap. Place the other end of the hose in a suitable drain container. A clean, clear container is ideal (i.e. Mason jar) so that the drained fuel can be inspected for water and other contaminants.

• Rotate the drain valve (indicated in image) counterclockwise until fuel begins to drain.

• Once the fuel filter housing has drained completely, remove the cap with a 28 mm socket; the fuel filter will be attached to the cap.

• Discard the old fuel filter by pulling it off of the cap. Inspect the inside of the cap for metallic debris (particularly on CP4 equipped 2019 and 2020 model year vehicles), which could indicate an injection pump failure is eminent.

• Install the lubricated fuel filter housing cap o-ring.

• Insert the new fuel filter into the cap so that it is secured in place.

• Reinstall the fuel filter/cap assembly into the housing. Secure the cap hand tight and verify that the o-ring has sealed properly, then torque to 22.5 ft-lbs (30.5 N-m) with a 28 mm socket; do not overtighten.

• Verify that the drain valve is closed. Cycle the engine to the "run" position (do not attempt to start) 5 to 10 times to prime the chassis mounted filter housing before replacing the engine mounted filter.

• Locate the engine mounted fuel filter housing on the driver side of the engine block just inwards of and slightly below the brake fluid reservoir.

• From beneath the vehicle, locate the fuel filter housing drain hose protruding from the bottom of the fuel filter housing (pictured).

• Use an appropriate fitting to connect a section of tubing to the drain hose. If using a barbed fitting, do not fully insert the fitting into the drain hose as the connection may become permanent. Only insert the fitting enough to ensure it will not leak or detach while the fuel bowl is draining.

• Place the opposing end of the tubing into an appropriate drain container. A clean, clear container is ideal (i.e. Mason jar) so that the drained fuel can be inspected for water and other contaminants.

• Rotate the yellow drain valve at the base of the fuel filter housing (pictured) 1/4 turn counter-clockwise and allow the housing to drain completely.

• While the fuel bowl is draining, lubricate the new filter housing lid o-ring with clean engine oil.

• Lubricate the outer fuel filter seal (integrated into the filter element) and inner plastic ring (oval shaped ring) with clean engine oil.

• Install the new fuel filter, then remove and replace the old fuel filter housing lid o-ring (recommend installing new filter before replacing o-ring to avoid dropping debris into filter housing). The fuel filter stand pipe is oval shaped and therefore you may have to rotate the filter element to find the correct position.

• Close the yellow drain valve completely.

• Reinstall the fuel filter housing lid and torque to 22.5 ft-lbs (30.5 N-m).

• Cycle the ignition to the "RUN" position (do not start or attempt to start) until the electric fuel pump powers down, then cycle the ignition to the "OFF" position. Repeat this process 10 to 12 times in order to prime the fuel system.

• Start the engine and check for leaks at the fuel filter housing lids and drain valves.

• Inspect the diesel fuel drained from the filter housings; clean diesel fuel should be clear with a blue or green hue. Cloudy, milky, orange, or dark colored fuel will generally indicate a fuel contamination issue.