Applicable Models:

2011 - current Ford F-250, F-350, F-450, F-550 Super Duty

2021 - present Ford F-600 Super Duty

2015 - present Ford F-650, F-750 medium duty trucks

Applicable Engine(s):

6.7L Power Stroke diesel

Engine Oil Capacity:

13.0 quarts with filter change for 2011 - 2022 model F-250 - F600

15.0 quarts with filter change for 2023+ model F-250 - F-600

15.0 quarts with filter change for 2015 - 2022 model F-650/F-750

17.0 quarts with filter change for 2023+ model F-650/F-750

Engine Oil Viscosity Spec:

See full viscosity chart below for options and requirements

Oil Change Intervals:

Change engine oil and oil filter as prompted by the oil life monitor system

2011 - 2022 model vehicles - do not exceed 10,000 miles between oil change intervals

2023+ model vehicles - do not exceed 15,000 miles between oil change intervals

The 2011 to 2022 Ford Super Duty has a maximum oil change interval of 10,000 miles and an engine oil capacity of 13.0 quarts with filter change. For 2023 models, the engine oil capacity was increased by 2 quarts to 15.0 quarts with filter change and the maximum oil change interval was increased to 15,000 miles. Note that all 6.7L Power Stroke equipped vehicles feature an intelligent oil life monitoring system, which takes driving conditions into consideration and prompts the operator when an oil change is required.

Under no circumstances should the maximum oil change interval be extended. Due to fuel dilution problems, we highly recommend that all 6.7L Power Stroke owners adhere to a maximum 5,000 mile oil change interval unless an oil analysis regiment is adopted in order to monitor fuel dilution rates between oil changes.

Fuel Dilution in 6.7 Power Stroke Engines

Fuel dilution is a widely common problem in many modern diesel engine platforms, including the 6.7L Power Stroke, that are equipped with an exhaust aftertreatment system. The fundamental problem with the 6.7L Power Stroke is that raw diesel fuel is sent through the combustion chambers on the passenger side bank of cylinders during the exhaust stroke while the diesel particulate filter active regeneration cycle is in progress. This method of introducing fuel to the DOC, where it is consumed to produce extremely high exhaust temperatures, results in cylinder washing and fuel entering the crankcase.

The risks of fuel dilution are obvious; fuel entering the crankcase thins the lube engine oil, breaks down its molecular composition, and reduces is lubricating properties. Fuel dilution is typically considered normal if it does not exceed 5% between oil changes (5% diesel fuel by volume). Fuel dilution rates greater than 5% are considered abnormal and are often labeled severe when they exceed 7%. Note that some degree of fuel dilution is entirely normal in all diesel engines and what is considered excessive is the subject of debate.

Combating Fuel Dilution

Fuel dilution is going to inherently occur in high rates during each active regeneration cycle, however you can help minimize it by avoiding long periods of idling, ensuring that regeneration cycles are completed once initiated (i.e. drive until regeneration is completed, do not shut engine down during regeneration), and planning routes that avoid heavy stop-and-go traffic conditions. Additionally, regularly use the engine block heater during the cold Winter months to reduce engine warm up times.

Another method of combating fuel dilution is to increase the engine oil capacity; there's an obvious reason why Ford Motor Company added 2 quarts of oil capacity to the 2023 model year engines. Aftermarket engine oil pans (Mag-Hytec F6.7, PPE 314052110) and bypass filtration systems (Amsoil single remote bypass, Amsoil dual remote bypass) both offer solutions for adding several quarts of oil capacity to the 6.7L Power Stroke.

To better understand fuel dilution and how it affects your engine, employ an oil analysis service to test the fuel dilution level of your engine oil. Once you have a baseline of fuel dilution rates over a known mileage interval, modify oil change intervals to keep fuel dilution below 5%.

API Category & Ford Engine Oil Specifications

The engine oil requirements for the 6.7L Power Stroke are somewhat confusing, so let's begin with a brief history lesson. When the 6.7L Power Stroke was introduced for the 2011 model year, Ford required an API CJ-4 engine oil. This is a low ash formulation with performance characteristics that, amongst other things, provide protections against DPF clogging and minimizes deposits in EGR coolers and valves. In 2016, the American Petroleum Institute introduced the API CK-4 specification, which is assumed to exceed the performance characteristics of the CJ-4 spec. In testing CK-4 oil formulations, however, Ford Motor Company found that they did not always meet Ford's wear protection criteria and CJ-4 formulations were superior in this category (you can view the memo from Ford here).

For the 2011 model year, Ford required an engine oil that met WSS-M2C171-D specifications, but this spec is used synonymously with API CJ-4 in the owners manual. For 2012 to 2016 model years, Ford required an engine oil that met WSS-M2C171-E specifications, but this spec is used synonymously with API CJ-4 in the owners manual. For the 2017 - current model year, Ford has required an engine oil that meets WSS-M2C171-F1 specification; again, this spec is used synonymously with API CJ-4 in the owners manual.

The takeaway here is that Ford WSS-M2C171-F1 spec engine oils meet CK-4 standards, but CK-4 standards do not necessarily meet the Ford WSS specification. In summary, all 6.7L Power Stroke diesel owners should be using a motor oil that meets the Ford WSS-M2C171-F1 specification, which supersedes the previous Ford specs and will ensure maximum engine wear protection in addition to exhaust aftertreatment system compatibility. We highly recommend Amsoil Max Duty Signature series 5W-40 for all applications within its temperature range; it meets Ford specifications and provides additional protections against fuel dilution and engine wear while providing superior cold flow characteristics.

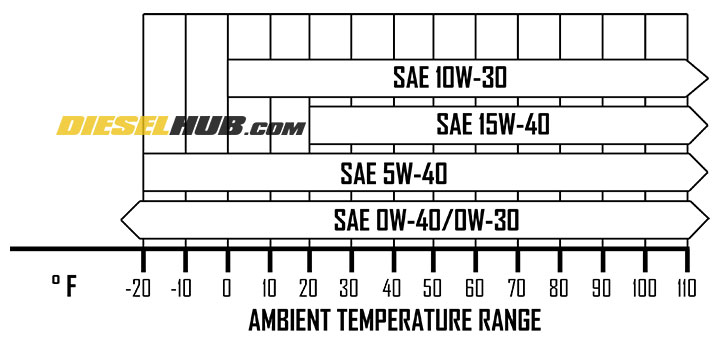

6.7 Power Stroke Engine Oil Viscosity Chart

| Ambient Temperature Range | Viscosity & Spec | Remarks |

| Expected ambient temp > 0° F | SAE 10W-30 API CJ-4 meeting WSS-M2C171-F1 specifications | [1] |

| Expected ambient temp > -20° F | SAE 5W-40 API CJ-4 meeting WSS-M2C171-F1 specifications | [2] |

| Expected ambient temp > 20° F | SAE 15W-40 API CJ-4 meeting WSS-M2C171-F1 specifications | [3] |

| All ambient temps | SAE 0W-30/0W-40 API CJ-4 meeting WSS-M2C171-F1 specifications | [4] |

[1] - Select for normal driving, not recommend for heavy towing

[2] - Required viscosity grade for vehicles falling under the "severe" or "heavy duty" service categories and vehicles operating on biodiesel blends

[3] - Acceptable viscosity grade for vehicles

operating on biodiesel blends, but not a substitute for 5W-40 for "severe" or "heavy duty" service conditions

[4] - Viscosity grades required for operating in ambient temperatures less than

-20° F; not advised in warmer temperatures

Severe/Heavy Duty Service Category Criteria

A vehicle that meets any of the following criteria is categorized under the "severe duty" service category:

- Engine is idled more than 10 minutes within a 60 minute drive period, is operated at low speeds (under 25 mph) for extended periods of time, or is frequently operated stationary.

- Vehicle makes short trips with frequent stops and/or engine is frequently operated in a manner that prevents it from reaching full operating temperature.

- Vehicle is driven off-road or in dusty conditions.

- Vehicle is driven/operated in temperatures below -9° F or above 100° F.

- Vehicle performs light to medium towing exceeding 1,000 miles between normal oil change intervals.

- Vehicles performs heavy trailer towing.

- Vehicle hauls cargo at or near it's maximum payload capacity for extended periods of time.

- Engine is run on fuels other than ULSD, including all biodiesel blends.

Most Super Duty pickup trucks will fall under the severe duty service category; recommend 5W-40 full synthetic engine oil so long as vehicle is operated in ambient temperatures greater than -20° F.

6.7 Power Stroke Motor Oil Recommendations

Diesel Hub recommends the following Amsoil products for Super Duty trucks equipped with the 6.7L Power Stroke V-8:

Amsoil Max Duty Signature Series 5W-40 diesel oil

Premium full synthetic motor oil for severe duty service

Amsoil Max Duty Signature Series 10W-30 diesel oil

Premium full synthetic motor oil for normal driving

Amsoil Max Duty Signature Series 15W-40 diesel oil

Premium full synthetic motor oil

Amsoil synthetic engine oils offer:

• Superior protection against fuel dilution and oil consumption

• Superior resilience against thermal, mechanical, and chemical breakdown of engine oil

• Improved oil flow and engine protection in sub-zero temperatures and during cold starts

• All listed products meet Ford engineering specification WSS-M2C171-F1

Amsoil is a leading manufacturer of synthetic oils and lubricants, including a line of engine oils engineered to meet the stringent demands specific to diesel engines.

6.7 Power Stroke Oil Change Parts List

| Description | Part Number(s) | Remarks |

| Engine oil filter | Motorcraft FL-2124S | [5] |

| Engine oil pan drain plug | Ford F75Z-6730-BA | [6] |

| Engine oil fill cap | Motorcraft EC786 | [7] |

| Engine oil level indicator (dipstick) | Ford BC3Z-6750-C | [8] |

[5] - Ford/Motorcraft lube oil filter is highly recommended, features silicone anti-drainback valve; FL-2124-S replaces the FL-2051-S oil filter

[6] - Reusable; examine threads and o-ring seal, replace as necessary

[7] - Reusable; examine condition of o-ring seal and replace as necessary, or replace if top of cap begins to deteriorate

[8] - Replace if dipstick is kinked, does not enter/exit dipstick tube smoothly, or if becomes damaged

Motorcraft FL-2051S vs FL-2124S Oil Filters

Ford Motor Company began phasing out the Motorcraft FL-2051S oil filter for the updated FL-2124S oil filter during 2022 in preparation for the 2023 variant of the 6.7L Power Stroke. The oil filters, albeit dimensionally similar, are quite different internally and the transition represents much more than a simple part number change. Ford has noted that the FL-2051S and FL-2124S oil filters are backwards compatible, meaning either oil filter can be used on any 6.7L Power Stroke application.

Dimensionally, both oil filters are identical and feature silicon anti-drainback valves, which is the preferred material for such devices as it tends to resistant chemical and heat degradation better than common rubber and plastic materials, both of which can be found in less desirable filtration products.

The major difference between the obsolete FL-2051S and new FL-2124S is the latter's synthetic filter media. Although both filter elements contain a total of 57 pleats, the FL-2124S filter element weighs 1.6 ounces more. While this may not seem significant, this equates to a 21% greater filter mass. Visually, the difference in filter media composition and density is quite obvious. Where the FL-2051S has thin pleats and a pinkish beige undertone, the FL-2124S is bright white and the pleats and noticeably thicker.

The inlet ports on the two oil filters are also different, with the FL-2051S having 8 round inlet ports and the FL-2124S having 5 oval inlet ports. The gasket thicknesses and diameter are identical between the two oil filters. In summary, there's no reason to seek out what is left of the FL-2051S stock. The new FL-2124S is the superior engine oil filter and moving forward should be used on all 6.7L Power Strokes.

6.7 Power Stroke Ticking Noise After Oil Change

It is not uncommon for a 6.7L Power Stroke to produce a typewriter-like ticking noise following an oil change. Ford technical service bulletin (TSB) 10-19-2 addresses this concern and assures that it is completely normal. In fact, it is not uncommon for this sound to come-and-go under various conditions. There's no reason to be alarmed if your engine begins producing this noise, even for extended periods of time. The TSB can be viewed here: Ford TSB 10-19-2

How to Change the Engine Oil in a 6.7 Power Stroke

Click any thumbnail to view fullsize, detailed image

• Locate the engine oil drain plug and filter. The drain plug is located near the bottom of the engine oil pan and points towards the rear of the vehicle. The lube oil filter is located near the passenger side of the engine oil pan.

• Place a suitable container (minimum 13 quarts capacity) beneath the engine oil pan to collect the used oil as it is drained.

• Remove the drain plug (16 mm socket or box end wrench) from the engine oil pan and allow the engine oil to drain.

Note that 2011 model year engines had a plastic lower oil pan and a 1/4 turn style drain plug, differing from that pictured.

• Locate the engine oil fill cap on top of the engine towards the driver side near the dipstick and dipstick tube.

• Loosen the engine oil fill cap to allow the oil to drain from the oil pan freely (the cap does not need to be removed, just loosened to allow the crankcase to vent).

• Remove the engine oil filter by rotating it counterclockwise. An oil filter wrench can be used as necessary.

• Verify that the engine oil filter gasket did not stick to the oil filter adapter base. Note that in the filter adapter pictured, the gasket has separated from the filter and stuck to the base of the adapter; it is imperative that this is removed before attempting to install the new oil filter.

• Clean the engine oil filter adapter base/flange with a clean, lint free cloth.

• Carefully examine the condition of the engine oil drain plug, ensuring that the threads are not damaged and that the o-ring seal is in good condition. If the seal appears flattened or has a rip, tear, etc, replace the drain plug.

• Clean the drain plug with a lint free cloth. Do not clean the drain plug with a chemical or solvent (i.e. brake cleaner) as it may compromise the o-ring seal.

• Reinstall the drain plug in the engine oil pan; torque to 19 lb-ft. Clean the area around the drain plug so leaks can be easily detected.

• Pre-fill the new oil filter and lubricate the gasket with clean engine oil. Pre-filling the filter prevents an entirely dry start, which over time will cause undesirable wear. Do not overfill the filter as it will spill during installation (approximately 3/4 of a quart of oil is sufficient and allows the filter to be maneuvered without spilling).

• Install the new oil filter snug to the oil filter adapter base. Clean any new or used engine oil that may have spilled so that leaks can be easily detected.

• Add 13 quarts (minus what was added to the engine oil filter) of new motor oil through the oil fill using a clean funnel. When selecting oil, be mindful of the compatible ambient temperature ranges listed in the oil viscosity chart above.

• Reinstall the engine oil fill cap once the crankcase has been refilled.

• Check for oil leaks at the oil drain plug now that that crankcase has been filled.

• Remove the engine oil level indicator (dipstick) from its tube, wipe it clean with a lint free cloth, then reinsert completely and remove again. Verify that the engine oil level is correct.

• Start the engine and check for leaks at the oil drain plug and around the base of the oil filter.

• Reset the engine oil life monitor through the instrument panel display by first scrolling to "Truck Info", then "Maintenance Monitor", and finally "Oil Life" using the buttons on the steering wheel. Hold the "OK" button on the steering wheel to reset to 100%.

• Every oil change is an opportunity to collect a sample for oil analysis. Oil analyses detect and report important information such as the concentration of wear metals in the engine oil, total fuel dilution, and detect contaminants such as engine coolant.

• We highly recommend the oil analysis services provided through Oil Analyzers Inc for prompt service and comprehensive reporting.

• Our oil analysis results indicated moderate levels of wear metals in the engine oil. Since this is the vehicle's first oil change, this is to be expected due to engine break-in. Fuel dilution was approaching 5%, which is moderately high. The oil will be re-sampled at the next oil change to determine whether or not this is also due to engine break-in, or if it will be considered a normal baseline for future samples.