Applicable Models:

1994.5 - 1997 Ford F-250, F-350, F-Super Duty

1999 - 2003 Ford F-250, F-350, F-450, F-550 Super Duty

2000 - 2003 Ford Excursion

1995 - 1999 Ford Econoline E-350

2000 - 2003 Econoline E-350, E-450, E-550

Applicable Engine(s):

7.3L Power Stroke V-8 diesel (7.3 DIT, T444E)

Engine Oil Viscosity:

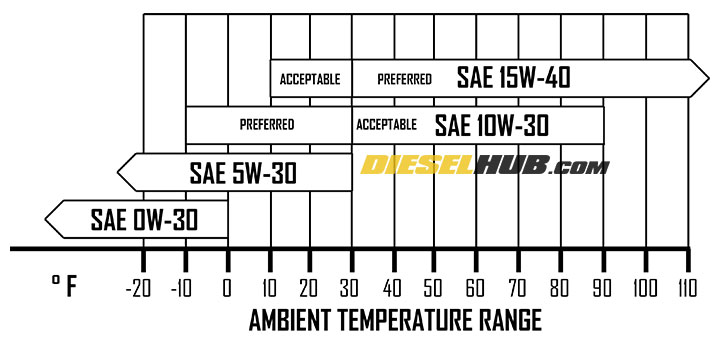

Refer to viscosity chart below

7.3 Power Stroke Oil Change Intervals

Ford Motor Company recommends changing the engine oil and filter every 5,000 miles or 6 months under normal usage and every 3,000 miles or 3 months for severe conditions. Mileage and time intervals are taken at whichever comes first, not whichever is more convenient. By today's standards, "normal usage" assumes heavily ideal conditions with no towing, minimal idling, and light traffic conditions. The overwhelming majority of 7.3 Power Stroke equipped vehicles will fall under the "severe" maintenance category. Furthermore, the aging 7.3 Power Stroke engine's that remain in service today will benefit from the more stringent maintenance regiments. Custom intervals can be established by incorporating an oil analysis into the maintenance routine.

For the 7.3 Power Stroke, and HEUI engines like it, motor oil is more than a lubricant; it also serves as a working fluid for the injection system. Regularly scheduled oil changes are thus critical to the life of even the fuel system's many moving components. As part of the HEUI process, oil pressure in the high pressure circuit often exceeds 2,000 psi - an additional wear mechanism that this engine's oil is exposed to.

Fuel Dilution in 7.3 Power Stroke Engines

Fuel dilution is an entirely normal phenomenon in any diesel engine, but it occurs at higher rates when combustion temperatures are low and/or engine loads are high. Fuel dilution is the contamination of diesel fuel in the engine's lube oil supply. Diesel fuel sticks to the cylinder walls and is moved into the crankcase by the piston rings or is forced into the crankcase past the rings during the compression stroke.

Excessive fuel dilution is typically categorized as more than 5% diesel fuel in the engine oil, by volume. Diesel fuel dilutes the engine oil, lowering its viscosity and chemically breaking down the composition of the oil. For these reasons, excessive fuel dilution can ultimately be the source of accelerated engine wear. Excessive fuel dilution can be caused by:

- Excessive idling, especially in cold ambient temperatures.

- Frequent driving in stop-and-go traffic conditions.

- Worn piston rings and/or cylinder walls (excessive or irregular clearance between piston rings and cylinder walls).

- Clogged crankcase ventilation system preventing diesel fumes from being separated from the engine oil.

- Poor warm up routines during cold weather operation, especially prior to towing.

- Failure to use an engine block heater in extreme cold weather.

Oil Consumption in 7.3 Power Stroke Engines

In all reality external oil leaks are more likely than significant engine oil consumption, but assuming the engine oil level is decreasing and there are no serious gasket or seal leaks excessive oil consumption can result from:

- Severely worn piston rings and/or cylinder walls.

- Severely clogged air filter, resulting in excessive intake vacuum pulling through the crankcase vent.

- Compromised turbocharger oil seal(s).

- Engine oil cooler leak (accompanied by oil in the engine coolant).

- Cracked injector cup(s) (accompanied by oil in the engine coolant).

Checking for external leaks is relatively easy; if the vehicle is leaving oil stains where it is parked, it is leaking some form of lubricant. Note that it only takes a little oil to create a large stain on concrete or pavement. These engines will begin to consume some oil as they age due to normal and unpreventable wear. We would consider oil consumption excessive when more than 1 quart is lost between oil changes (assuming there is minimal loss due to external oil leaks).

Soot Contamination in 7.3 Power Stroke Engines

Soot contamination of engine oil is also a relatively unavoidable reality for all diesel owners. Soot particles are largely abrasive and excessive soot contamination of the engine oil can result in accelerated wear thus excessive contamination is unfavorable. The combustion of diesel fuel produces soot, and some of this soot is going to find its way into the crankcase - period. A bypass oil filtration system is an economical solution to fighting soot contamination as these systems employ more efficient filters capable of capturing significantly smaller particles than a standard full flow engine oil filter. Excessive soot contamination is generally identified in an oil analysis and can be caused by any combination of the following:

- Aftermarket performance enhancing devices that cause moderate to excessive tailpipe smoke. Consider the fact that these combustion byproducts were produced in the cylinders of the engine, some of which will have infiltrated the crankcase.

- Severely worn piston rings and/or cylinder walls.

- Frequently "lugging" the engine by operating at high loads and low engine speeds.

- Poor warm up routines during cold weather operation, especially prior to towing.

You may notice that the engine oil in your 7.3L Power Stroke turns black quite quickly. This is due, in part, to the fact that the high pressure oil pump reservoir and oil cooler do not get drained during an oil change. For owners wanting to go a step further, the reservoir can be drained with a fluid extraction pump though the access port incorporated into the cover (see figure 1 below).

Simply remove the access plug and extract the engine oil. After the primary system has been changed, refill the reservoir to within 1 inch of the top of the reservoir (do not overfill, leave a 3/4 to 1 inch air gap). You will need an addition 3/4 to 1 quart of engine oil in addition to the sump and filter's 15 quart capacity. There is no feasible remedy for completely draining the oil cooler without removing it from the engine.

Water in Engine Oil & Engine Oil in Coolant

Water in the engine oil and/or engine oil in the coolant is typically the result of oil cooler o-ring or injector cup failure. Large o-rings isolate the engine oil and coolant passages of the oil cooler and it only takes a small crack or defect to allow the two fluids to mix. Engine oil generally contaminates the coolant while the engine is running since the working pressure of the oil is higher than that of the coolant. Depending on the type of failure, coolant tends to contaminate the engine oil while the engine is off. The best test for this is to pressurize the cooling system and check for engine oil contamination. If the cooling system does not hold pressure and water is found in the engine oil, the oil cooler is highly likely to be the culprit.

Each fuel injector on a 7.3 Power Stroke rests in a copper sleeve often referred to as the cup. A series of o-rings installed along the body of the injector seal off fuel and oil passages cast into the cylinder head. When one or more injector cups develop a crack, it creates the possibility for coolant to mix with fuel and/or engine oil. It is rare for a cracked injector cup to cause significant water in the engine oil, but this is the common culprit in cases where diesel fuel is found in the engine coolant.

Engine Oil Analysis

An engine oil analysis is cheap insurance against otherwise undetected engine problems. Such a test can detect fuel dilution and soot contamination levels, wear metal concentrations, oil condition (viscosity, base number, and additive levels), and water contamination (indicative of coolant contaminating the engine oil). These services are not terribly expensive and, in lieu of submitting samples at every oil change, we highly encourage at least an annual oil analysis. An oil analysis can also be useful in determining adequate oil change intervals for high mileage or heavy duty type service vehicles. We recommend Oil Analyzers, a service offered in cooperation with Amsoil Inc, for their value and the comprehensive nature of their tests.

7.3 Power Stroke Oil Change Parts List

| Part Description | Part Number(s) | Remarks/Notes |

| Engine oil filter | Motorcraft FL-1995-A | --- |

| Oil pan drain plug | Ford F6TZ-6730-AA | --- |

| Drain plug gasket | Ford 3C3Z-6734-AA DP-110103 |

[1] |

| Oil fill cap | Motorcraft EC-743 | --- |

| Engine oil dipstick | Ford F81Z-6750-DA | --- |

| Engine oil dipstick tube | Ford F8Z1-6754-AA | --- |

| Engine oil | See viscosity chart below | --- |

| Oil additive | Archoil AR9100 friction modifier | [2] |

[1] - Drain plug gaskets are one time use and should be replaced at every oil change.

[2] - The 7.3 Power Stroke and 6.0 Power Stroke engines are the only two applications for which we will ever recommend a supplemental oil additive. Specifically, Archoil AR9100 friction modifier prevents and even eliminates stiction in HEUI fuel injectors when used periodically. Oil additive is not a Ford requirement, but helps to prevent and alleviate injector problems related to stiction. Using a high quality synthetic motor oil may also help circumvent certain problems related to stiction.

FL1995 vs FL1995A Oil Filters

Around 2020, Ford Motor Company began phasing out the Motorcraft FL1995 (FL-1995) oil filter and replacing it with Motorcraft part number FL1995A (FL-1995-A). This proved to be more than just a part number supersession, as the FL-1995-A is noticeably different internally to the previous FL-1995. For all intents and purposes, there is no visible design aspect to suggest the newer filter is of any less quality. In all likelihood, the FL-1995-A oil filter is an improvement to the FL-1995. The new filters are also not cheaper, foreign made alternatives; Ford labels both oil filters as "majority content made in USA". For those interested, we've documented the differences in the table and figures below.

| Motorcraft FL-1995 | Motorcraft FL-1995-A | |

| Canister height | 7-15/16 inches | 8-1/16 inches |

| Canister diameter | 4.25 inches | 4.25 inches |

| Weight | 29.8 ounces | 35.1 ounces |

| Gasket profile | Trapezoidal | Square |

| Pleat count | 72 | 69 |

| Pleat depth (approximate) | 0.725 inch | 0.735 inch |

| Pleat height (approximate) | 6.50 inches | 6.50 inches |

| Media diameter | 3.725 inches | 3.944 inches |

The FL-1995-A is slightly taller than the FL-1995 and marginally heavier. There is a slight difference in the color and dimensions of the filter medias (see figure 2), but there is no visual evidence that they are significantly different. The spring mechanism at the base of the FL-1995-A is much more robust. The square profile gasket on the FL-1995-A is likely to provide a more reliable seal than the trapezoidal profile gasket on the FL-1995. Case-in-point, our inspection did not uncover any evidence to suggest the new filter is inferior in any way.

7.3 Power Stroke Motor Oil Viscosity Chart

Figure 4 below depicts suitable viscosity grades as they correlate to the anticipated ambient temperature. The ambient temperature in which the vehicle will be operated is the single most important factor that determines engine oil viscosity selection. Note that Ford provides "acceptable" and "preferred" ranges for SAE 15W-40 and 10W-30 engine oils. Ideally, an engine oil viscosity that is preferred within an ambient temperature range should be selected. For example, while a 10W-30 oil is acceptable in temperatures between 30 and 90°F, a 15W-40 engine oil would be preferred in this temperature range.

7.3 Power Stroke Engine Oil Recommendations

Diesel Hub recommends the following products for the 7.3 Power Stroke equipped Ford F-Series and Super Duty:

Amsoil Signature Series Max Duty 15W-40 diesel oil - Superior diesel oil for maximum engine protection

Amsoil Heavy Duty 15W-40 diesel oil - Premium diesel oil for next-level engine protection at an economical price - best value

Amsoil Signature Series 10W-30 diesel oil - Superior flow and cold start protection in cold weather - recommended within temperature range

Amsoil synthetic engine oils offer:

• Superior protection against fuel dilution and oil consumption

• Superior resilience against thermal, mechanical, and chemical breakdown of engine oil

• Improved oil flow and engine protection in sub-zero temperatures and during cold starts

Amsoil is a leading manufacturer of synthetic oils and lubricants, including a line of motor oils engineered to meet the demands specific to diesel engines, old, aging, or new.

How to Change the Engine Oil in a 7.3L Power Stroke Diesel

Click any thumbnail to view fullsize, detailed image

- Ensure that the vehicle is in park (automatic transmission ) or in gear (manual transmission) and that the parking brake is engaged. Caution - never change oil when the engine is hot.

- Place a drain pan with a minimum 15 quart capacity beneath the engine oil pan drain plug.

- Loosen the oil drain plug with a 3/4 inch socket or wrench, then unthread completely by hand.

- Locate the engine oil fill cap on the passenger side of the engine, just behind the alternator (early engines) or AC compressor (later engines).

- Loosen the engine oil fill cap to help vent the crankcase and allow the engine oil to drain smoothly.

- While the oil pan is draining, locate and loosen the engine oil filter (passenger side between the frame rail and oil pan). If the filter is stubborn, an oil filter wrench/pliers can be used. Emery cloth wrapped around the cannister can also be used for added grip.

- Allow the filter to drain for several minutes before removing.

- Thoroughly clean the oil pan drain plug, including any materials stuck to the magnet (if applicable). Discard the old gasket; crush type washers are not intended for multiple uses and it is highly likely to leak if reused.

- Verify the condition of the oil pan drain plug. Drain plugs with damaged threads or rounded heads should be replaced.

- Install a new drain plug gasket onto the drain plug.

- Optional - slowly fill the new oil filter with roughly 1/2 to 3/4 quarts of clean engine oil. If the new engine oil is not being dispensed from new, clean, unopened containers, we do not recommend prefilling the filter.

- Lubricate the oil filter gasket with clean motor oil.

- Thoroughly clean the oil filter mounting base and verify that there are no remnants of the old gasket stuck to it (this is common).

- Install the new oil filter, tightening by hand. Typical torque is set by tightening the oil filter 3/4 to 1 full turn after the gasket has made contact.

- Reinstall the drain plug with new gasket. Torque the drain plug to 28 lb-ft. Failure to torque the drain plug properly will not seat the gasket and a leak is likely to develop.

- Add 15 quarts (minus what may have been added to the new oil filter) of new motor oil through the oil fill, then replace the cap.

- Verify that the oil pan drain plug is not leaking.

- Start the engine and verify that there are no leaks around the oil filter assembly.

- Turn the engine off and allow the vehicle to sit for 5 minutes, then verify proper oil level once more.