Renewable diesel has been an available petroleum diesel fuel substitute in California for many years and its prevalence along the West Coast is growing quite rapidly. There's nothing alarming about renewable diesel itself - albeit more expensive, it seems to be as drop-in compatible as the data suggests and has an excellent storage life. But evidence has surfaced that proposes significant complications in the blending of renewable diesel (HVO) and biodiesel (FAME). Furthermore, current labeling requirements do not always properly distinguish biodiesel as a blending component in renewable diesel fuel blends.

This is concerning for both modern and older vehicles due to the very limited storage life of biodiesel and its tendency to form acids as it oxidizes. For engines that do not meet the current maximum B20 compatibility standards, the problems could be more severe due to fuel tanks and systems utilizing materials that are not compatible with biodiesel. Brass, for example, is known to accelerate degradation and increase sediment formation when it is exposed to biodiesel.

By design modern vehicles with biodiesel compatibility would not employ incompatible materials in the fuel system. This leaves the fuel tanks and systems of older vehicles and equipment particularly vulnerable to biodiesel related corrosion and failures. A blend of 95 percent renewable diesel and 5 percent biodiesel that was stored in a steel fuel tank for 3 to 4 months was responsible for clogging the fitting featured in figure 1 above.

Under ordinary conditions I would attest that 5% biodiesel by volume is not a potent enough blend to cause such severe issues. However, as I would later uncover, the impurities in biodiesel have a tendency to precipitate in the presence of renewable diesel. This increases the free fatty acid (FFA) content and further reduces the storage life of the fuel blend. Furthermore, the labeling of the fuel blends in question are not particularly forthcoming on the actual biodiesel content - if you have become accustom to renewable diesel labels, they do not necessarily distinguish between the two bio-fuels.

Renewable Diesel is Not Biodiesel

Renewable diesel is not biodiesel and biodiesel is not renewable diesel, but both fuels are in the bio-mass diesel family. While this may seem confusing at first, it's important to understand that these two fuels are produced via different processes and the resulting compounds are quite different. Both biodiesel and renewable diesel are produced from the same feedstocks - any combination of vegetable oils and animal fats - and thus they satisfy the bio-mass criteria.

Biodiesel and renewable diesel are trade names of sorts. The technical term for biodiesel is fatty methyl esters (FAME). Renewable diesel can be referred to as hydrotreated or hydrogenated vegetable oil (HVO). At face value both fuels are substitutes for petroleum diesel fuel and engines will run as intended on any of these fuels or mixtures thereof.

Biodiesel is in the ester family and is commonly produced from a process known as transesterification. A catalyst and an alcohol is added to the feedstock to induce a chemical reaction that separates the glycerol component of a triglyceride molecule from the fatty acid chains. Glycerol sinks to the bottom of the reaction vessel and is discarded. What remains are fatty acid chains, the esters, that we know as biodiesel.

Renewable diesel is a hydrocarbon in the exact manner that petroleum diesel fuel is. It is commonly produced through a process known as hydrotreating, where the feedstock is treated with hydrogen at elevated temperature and pressure. The reaction with hydrogen gas is what ultimately transforms the feedstock into a hydrocarbon fuel instead of an ester.

At the molecular level HVO is extremely similar to petroleum diesel fuel while FAME is not. HVO must adhere to the same fuel standards (ASTM D975) and specifications as petroleum diesel fuel. Biodiesel has its own set of standards (ASTM D6751) which define separate performance expectations and impurity limits. HVO is a very stable hydrocarbon that can be stored for long durations without consequence. Biodiesel is a "use it or lose it" fuel that is hypersensitive to oxidation. Natural water absorption and contact with certain metals accelerates the degradation process, resulting in acid formation.

The compatibility of HVO is aligned with that of diesel fuel and there are no special considerations regarding the storage or use of this fuel; it is a drop-in replacement meeting the same fuel standards. Although modern engines are certified to use fuel blends with up to 20% biodiesel, manufacturers provide varying guidance with regard to storage and usage of fuel blends that contain biodiesel.

"Biodiesel fuel has poor oxidation stability which can result in long term storage problems. Fuel produced to approved ASTM standards, if stored properly, provides for protection against fuel oxidation for up to six months." - 6.7 liter Cummins and 3.0 liter EcoDiesel engines [1]

"If the vehicle is not driven often and uses little fuel, or if it is stored for extended periods of time, avoid the use of biodiesel blended fuels above 5% by volume. When the vehicle is stored for longer than one month, it should be run out of biodiesel to below one-quarter tank, refueled with biodiesel-free fuel, and driven several kilometers (miles) before storage." - 6.6 and 3.0 liter Duramax engines [1]

"If you plan to park or store your vehicle for more than 1 month, then you should empty your vehicle fuel tank of biodiesel fuel. You should fill the tank with a pure petroleum-based diesel fuel and run your vehicle for a minimum of 30 minutes." - 6.7 liter Power Stroke engines [1]

It is not uncommon for manufacturers to recommend shortened fuel filter replacement intervals or even alternative engine oil viscosities when biodiesel blends are used.

[1] - Information retrieved from the applicable 2023 model year diesel supplement manual. This specific guidance is repeated in prior and subsequent manuals.

Misleading Pump Labels

Current labeling standards for biofuels are governed under Federal Law. Chapter 152 of Title 42 of United States law requires that:

(1) Biomass-based diesel blends or biodiesel blends that contain less than or equal to 5 percent biomass-based diesel or biodiesel by volume and that meet ASTM D975 diesel specifications shall not require any additional labels.

(2) Biomass-based diesel blends or biodiesel blends that contain more than 5 percent biomass-based diesel or biodiesel by volume but not more than 20 percent by volume shall be labeled "contains biomass-based diesel or biodiesel in quantities between 5 percent and 20 percent".

(3) Biomass-based diesel or biodiesel blends that contain more than 20 percent biomass based or biodiesel by volume shall be labeled "contains more than 20 percent biomass-based diesel or biodiesel".Source: U.S. Title 42, chapter 152, subchapter II - 42 USC 17021: Biomass-based diesel and biodiesel labeling

The Federal Trade Commission offers more specific labeling guidance, including minimum label sizes and color coding information. Moreover, for biodiesel blends between 5 and 20 percent and biomass-based diesel (i.e. renewable diesel) blends greater than 20 percent, the FTC requires:

For biodiesel blends containing between 5 percent and 20 percent biodiesel by volume:

The capital letter “B” followed immediately by the numerical value representing the volume percentage of biodiesel in the fuel (e.g., “B20”) and then by the term “Biodiesel Blend”; or (B) The term “Biodiesel Blend.”

For biomass diesel blends containing more than 20 percent biomass-based diesel by volume:

The numerical value representing the volume percentage of biomass-based diesel in the fuel followed immediately by the percentage symbol (e.g., “20%”) and then by the term “Biomass-Based Diesel Blend”; or (B) The term “Biomass-Based Diesel Blend.”

...the black band at the top of the label shall contain the numerical value representing the volume percentage of biomass-based diesel in the fuel followed immediately by the percentage symbol (e.g., “70%”) and then the term “Biomass-Based Diesel Blend.” In addition, the words directly underneath the black band shall read “contains more than 20 percent biomass-based diesel or biodiesel.”

Source: FTC Title 16, chapter 1, subchapter C, part 306 - Label Specifications

I have personally yet to come across a fuel station that has specifically indicated its biodiesel content when it is used as a blending agent in renewable diesel. The required "contains more than 20 percent biomass-based diesel or biodiesel" label for biomass-based diesel blends immediately becomes an umbrella for the biodiesel content, whether it exists or not, and therefore circumvents the requirement that, for example, a 95% renewable diesel, 5% biodiesel blend be labeled "B5" or "contains 5% biodiesel". The same could be said for a blend of 80% renewable diesel and 20% biodiesel, a blending ratio that is growing increasingly more common.

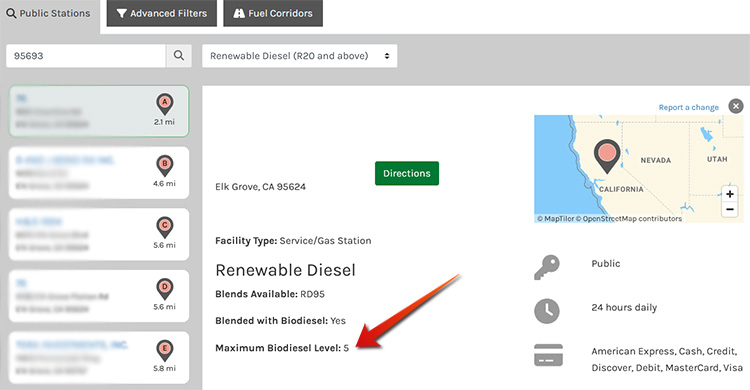

I have it on good authority that the fuel at this station (figure 2) is actually a blend of 95% renewable diesel and 5% biodiesel. To begin with, the fuel station was advertising its R95 renewable diesel blend in front of the station. Furthermore, the U.S. Department of Energy's biodiesel locator (figure 3 below) determined that as of July 2024 the diesel sold at this station was a blend of 95% renewable diesel and 5% biodiesel. If biodiesel falls under the biomass category, than the this label is technically accurate, but very misleading.

This specific fuel station and its misleading labels serve as the original inspiration for this article. Numerous, or dare I say countless biodiesel related equipment and component failures were traced back to fuel from this station.

Big Problems with Small FAME Concentrations

The vehicles and equipment in question share two things in common, 1) they were driven infrequently or stored for 3 to 6 months during Winter and 2) the primary source of fuel was the aforementioned R95, B5 blend. I wouldn't expect significant problems from small concentrations of biodiesel, but my experiences tell another story.

Corroded sending units, clogged fuel filters, leaking o-ring seals, carbon buildup in fuel line and fittings, and rusted fuel tanks are common symptoms of the spoiled fuel. Fuel pump failures and a honey-like residue at the bottom of fuel tanks are also a tell-tale sign of severe biodiesel contamination.

In each instance, the fuel that was drained off had similar characteristics. It reeked of varnish as if it were a batch of bad gasoline and had no lubricity whatsoever - it would actually cause some resistance when rubbed between two fingers. It was amber in color but ranged in opacity case-to-case. Samples from different sources precipitated the same white, milky substance at the bottom of the jar after they sat undisturbed for several days.

I would later theorize that the white substance were impurities precipitating from the biodiesel due to the fact that the description matched that of the impurities that are removed when biodiesel is washed. In fact, I made a quick batch for comparison; the substance drawn from the bottom of the sample jars was indistinguishable from the impurities I had just "washed" out of my small batch of biodiesel. My theory would ultimately prove highly probable, and it led me to investigate further into the interactions between HVO and FAME.

Blending FAME and HVO

The poor compatibility between HVO and FAME is not well documented, as if it does not fit the broader narrative that is being projected. I did stumble upon a useful document published by sustainable fuel producer Neste. From the "Neste Renewable Diesel Handbook":

"The poor solvent properties of [renewable diesel] increase the risk of precipitation of possible impurities of FAME, which even within fossil fuels can precipitate at temperatures above the cloud point."

"....the quality of FAME is an important factor; poor quality may result in problems, even at low concentrations. The precipitation risk of FAME's impurities increases with higher blending content."

"The precipitation risk decreases at higher temperatures."

Source: Neste Renewable Diesel Handbook

This particular section of the handbook goes on to detail that the lower the aromatic content of the fuel, the greater the risk that FAME impurities will precipitate; HVO has only trace aromatic hydrocarbon content. The evidence was mounting that biodiesel was the problem, even at such a low concentration. Additionally, my suspicions had been confirmed that there were some inherent challenges in the blending of these two fuels.

Studies suggest that renewable diesel has an excellent storage life and biodiesel does not, which poses an obvious question - why would anyone blend the two together? I've surmised that it's cost effective. Surely, fuel producers are more concerned with economics than the well-being of their customers equipment. So long as their fuels meet the necessary specifications and regulations, their liability is minimized.

As-produced FAME is an excellent lubricant that does not require post-treatment to meet minimum lubricity requirements. The opposite is true for HVO, which requires a heavy post-refinement treatment in the form of an additive package. Ultra low sulfur diesel is no different in that it requires an additive package to meet the lubricity requirements outlined in the ASTM D975 diesel fuel specification.

If we assume that commercial fuel additive treatments are more expensive than biodiesel at the appropriate blending ratio necessary to achieve minimum lubricity requirements, than biodiesel would be a more economical option in meeting this specification. It would take savings of mere pennies per gallon to equate to hundreds of millions of dollars in additional profit per year in the State of California alone [2]. If blending biodiesel is a more affordable treatment option, then it must be an attractive solution to such a business.

Regulatory incentives could also play a pivotal role, specifically in California. California's Low Carbon Fuel Standard incentives the production of environmentally friendly "bio" fuels in the form of credits. These credits are issued under the pretense that biofuels have a lower carbon intensity. Both renewable diesel and biodiesel meet these qualifications, but petroleum diesel does not. We can then formulate that a blend of renewable diesel and petroleum diesel may qualify for less credits than an equivalent blend of renewable diesel and biodiesel. In either of the aforementioned scenarios there may be significant financial incentives for the producers, and possibly the retailers of this fuel.

[2] - Based on 3.5 billion gallons for the year 2024 according to the California Department of Tax and Fee Administration (link) rounded up for convenience

Conclusion

Above all, this experience has shown me that there is insufficient clarity, oversight, and enforcement in the labeling of biodiesel fuel products. A person should not have to jump through hoops to find diesel fuel that is compatible with their vehicle and with all the well-known challenges and controversies engulfing biodiesel specifically, it should be clearly labeled at the refilling station.

This Costco location has made a clear attempt to distinguish its renewable diesel from biodiesel. I would go far to say that there is no biodiesel in this fuel, except that...

"Kirkland Signature™ Diesel only contains biodiesel where required by law, with the exception of Melrose, IL which is B11 due to market availability. However, up to 5% biodiesel may be found in CA, CO and OR. In California, biodiesel and regular petroleum are transported in the same pipelines and tankers."

Is this problem specific to California? The West Coast? It would seem so, for now, but there is a broader message to voice - be diligent in knowing what is going into your tank. Renewable diesel is not the bad guy here but I recommend that diesel owners attempt to avoid HVO fuels blended with biodiesel.