1994 to 1997 7.3 liter Power Stroke engines utilize a camshaft driven mechanical fuel pump while the later 1998 to 2003 model year engines feature an electric fuel pump. There are additional differences in the fuel systems of mechanical and electric versions and thus differences in pressure specifications and how fuel pressure is tested. 1994 to 1997 engines operate between 40 and 70 psi cranking or running at idle speed. Since the fuel pump is cam-driven, there will be large pulsations in the pressure reading. Naturally, as engine speed increases the time between pulsations should decrease proportionately. Ideally, fuel pressure peaks near 70 psi and does not drop below 40 psi.

1998 to 2003 engines have an electric fuel pump that should provide very constant pressure. The Ford specification is 30 to 80 psi (fuel pressure should not drop below 30 psi under any circumstances) but 50 to 60 psi at idle is much more common and a good, practical baseline target. If pressure is below 50 psi at engine idle, one or more conditions is contributing to abnormally diminished fuel pressure.

On these vehicles fuel pressure can be tested key on, engine off (KOEO), while the engine is cranking, and while it is running. In all these instances, fuel pressure should read very consistent and large fluctuations are not normal. The fuel pump will power ON for roughly 15 seconds during the glow plug preheat cycle, thus KOEO readings can be taken in lieu of doing so while cranking the engine over.

1994 to 1997 Engines

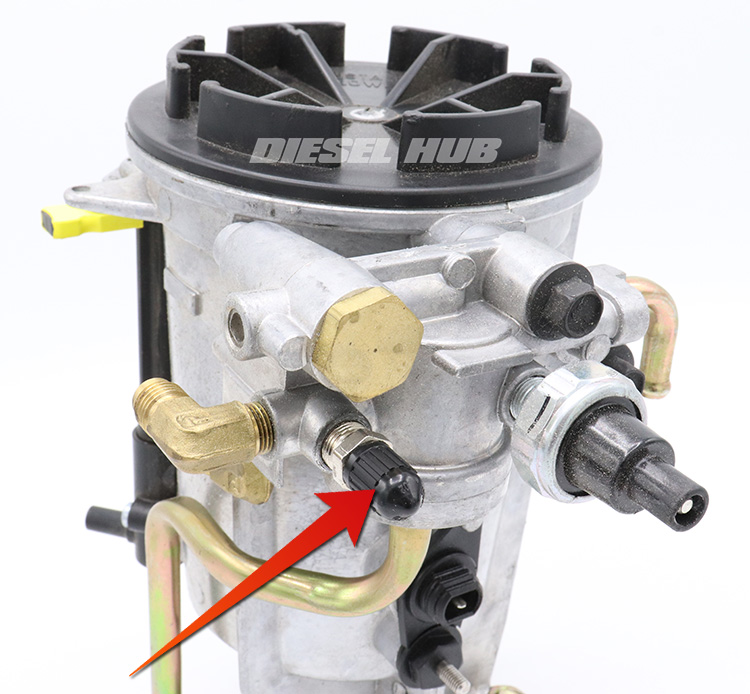

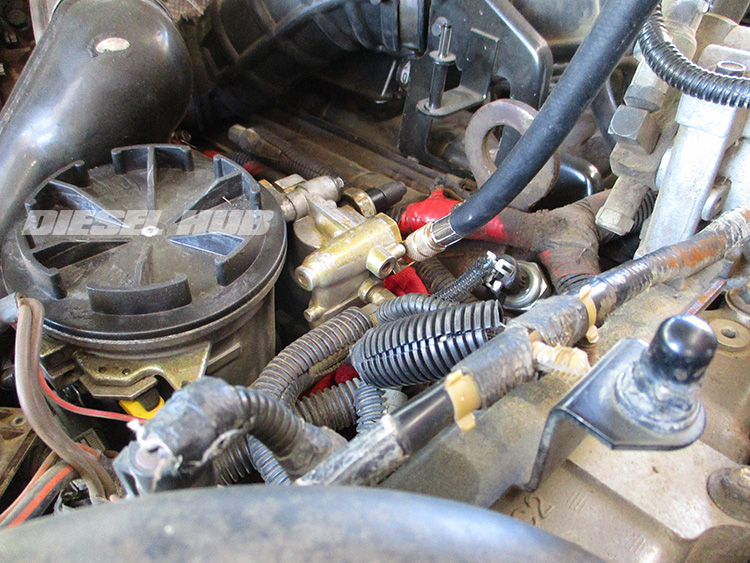

The fuel pressure test port on early engines is found on the pressure regulator housing of the fuel bowl (figure 2, below). It is positioned up front near the return lines on the fuel bowl and points towards the driver side fender. This location tests fuel pressure on the return circuit, thus fuel has traveled from the fuel pump, through the cylinder heads, and has been returned to the fuel bowl at the test port location.

The original test port requires a Ford style adapter. I have found these to be somewhat obsolete and often get referred to as the "old style" Ford test port. Updated test fittings are inexpensive, readily available (see test fitting 160401), and will convert to a 1/4 inch flare style fitting that is commonly used by modern test equipment. Often, no adapter is necessary when using this fitting. Common 1/8 inch NPT fittings (90 and 45 degree) can be used to redirect the test port to a more accessible angle but are not required.

1998 to 2003 Engines

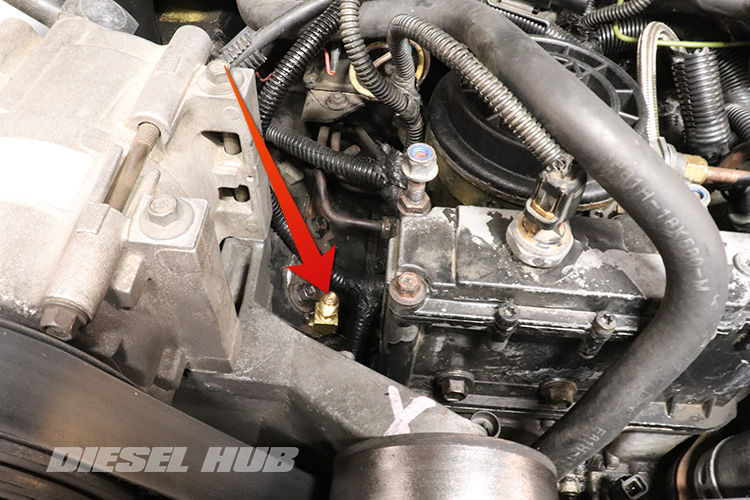

The later 7.3 liter Power Stroke engines are not factory equipped with a fuel pressure test port and the Ford procedure is to remove one of the pipe plugs in each cylinder head to attach test equipment. Unfortunately, the only location that is readily accessible is at the front, lower corner of the passenger side cylinder head and even this location has spacial restraints.

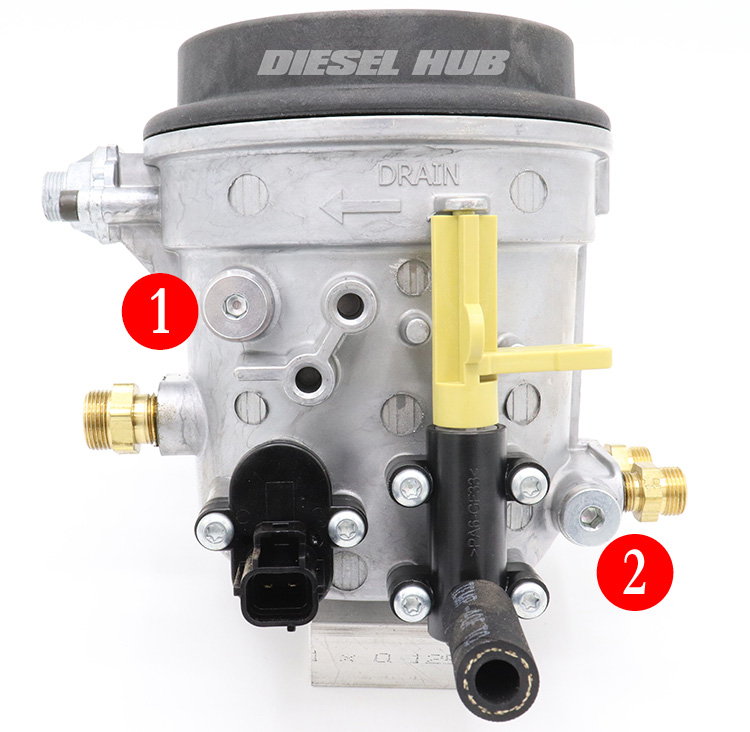

However, there are two plugs on the rear of the fuel filter housing that will accept test fittings (see 160501, fitting and adapters). The appropriate 1/4 inch flare test fitting can be permanently installed and are commonly compatible with modern test gauges without necessitating an adapter.

Referencing figure 4 below, a test fitting installed at the plug indicated by the number 1 measures the fuel pressure in the unfiltered section of the fuel bowl, i.e. this is the actual delivery pressure from the fuel pump to the filter housing. A test fitting installed at the plug indicated by the number 2 measures the fuel pressure at the outlet of the filter housing. This represents the fuel pressure as delivered to each cylinder head.

Fuel pressure is most often measured at the port labeled 1 because there is a higher risk of contamination in removing plug 2 - any foreign debris that enters the fuel system at this point will have bypassed the filter and will be carried to the cylinder head fuel galleries. Additionally, the only practical purpose for measuring fuel pressure here is to compare to a reading at 1 in order to identify a clogged fuel filter. Fuel sampling and a visual inspection of the fuel bowl is generally enough to identify a plugged filter.

It must be emphasized that fuel pressure should be very constant on systems with an electric fuel pump. Large fluctuations are evident of one more conditions - malfunctioning pressure regulator, in-tank sending unit damage, fuel aeration, etc. Furthermore, excessive "bubbling" noises coming from the fuel tank in combination with low or inconsistent fuel pressure most often allude to a problem with the sending unit foot or strainer, a condition that will require the fuel tank to be removed for inspection.

Cylinder Head Test Port Locations

Most conditions that are related to fuel pressure are easily diagnosed by taking pressure readings at the fuel filter housing. However, certain conditions may require testing fuel pressure at the cylinder heads to eliminate possible causes through process of elimination. Bearing in mind that the left and right cylinder heads are effectively identical, each cylinder head has an inlet/outlet to the fuel gallery at the front and rear of the casting. Figure 6 (below) identifies the front, passenger side cylinder head access port with a fuel pressure test fitting installed.

On the 1994 to 1997 engines, the fuel pump uses the two rearmost ports to supply fuel to the cylinder head galleries and the return lines connect at the two front-most ports. For 1998 to 2003 engines, fuel is supplied to the passenger cylinder head at the rear and the driver side cylinder head at the front (next to the HPOP reservoir); there is no return line to the fuel bowl on the later system.

Testing fuel pressure at the cylinder head ports only seeks to discover is there is a restriction inside the fuel galleries in the corresponding cylinder head; this circuit provides fuel to each of the eight fuel injectors. A restriction in these passages can only exist due to extreme contamination or wear metals dispersed due to a catastrophic failure in a mechanical component of the fuel injector. It is worth noting that the front passenger cylinder head access port is the most accessible while the driver side rear port is quite difficult to access without removing the turbocharger.