Applicable Models:

2003 - 2007 Ford F-250, F-350, F-450, F-550 Super Duty

2003 - 2005 Ford Excursion

2004 - 2010 Ford Econoline E-350

2003 - 2008 Ford F-650, F-750 medium duty trucks

Applicable Engine(s):

6.0 Power Stroke V8

Engine Oil Capacity:

15.0 quarts with filter change

Engine Oil Viscosity Spec:

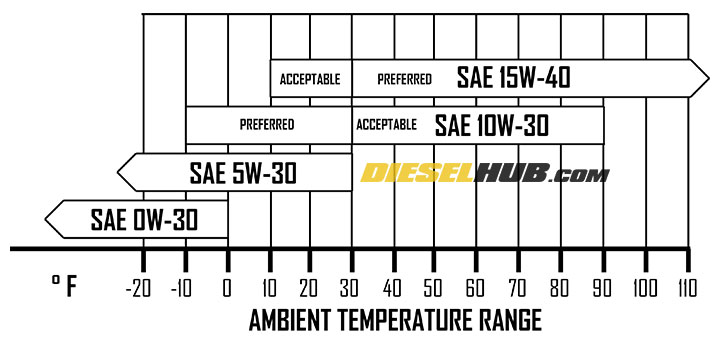

15W-40 common; see breakdown in viscosity chart below

Oil changes become a weightier subject when oil change intervals and motor oil selection is contemplated for engines employing HEUI injection systems, including the 6.0 Power Stroke. Although routine oil changes are of obvious important on any vehicle, the function of an HEUI system adds additional modes of motor oil breakdown, increasing the importance of timely service. In addition to lubricating the engine and all its moving parts, motor oil is also used as a hydraulic fluid in the high pressure oil circuit. Each fuel injector is its own intensifier, relying on high pressure engine oil to generate injection pressures that can reach 26,000 psi. This system is particularly sensitive to neglect and thus oil change decisions can have a significant impact on injector health.

Oil Change Intervals

The normal oil change interval prescribed to the 6.0 Power Stroke is 7,500 miles or 6 months, whichever should come first. The severe or heavy duty oil change interval is 5,000 miles or 6 months, whichever should come first. Note that most vehicles will fall under the severe/heavy duty category. The "normal" oil change interval generally assumes ideal conditions that rarely resembles the average driving environment. With age and mileage, it may be favorable to move towards more frequent service intervals as a means of maximizing engine longevity. The severe duty category is outlined by driving that includes any of the following conditions:

- Engine experiences frequent and/or excessive periods of idling; excessive idling is generally defined as 10 minutes or more of idle time during a 60 minute window.

- Vehicle is frequently driven in heavy stop-and-go traffic conditions.

- Vehicle makes frequent short trips in which the engine does not reach full operating temperature (with or without frequent engine shutdowns and restarts).

- Vehicle is used to tow light trailer(s) for more than 1,000 miles between oil change intervals.

- Vehicle is used to tow medium to heavy trailers/loads.

- Engine is run on biodiesel or biodiesel blends of any concentration. Note that the 6.0 Power Stroke is only factory certified for B5 (5% biodiesel, 95% conventional diesel fuel).

Many of these factors are subjective and left to interpretation but the bias should always lean towards the shorter oil change interval, which is the safer choice. Custom intervals can be determined for a vehicle by using an oil analysis service and taking oil samples at various intervals to determine at what point the lubricant being used is no longer suitable for service. This is an excellent strategy that will take into consideration fuel dilution and soot infiltration rates, both of which play a significant role in engine oil service life. Under certain conditions, it may be uncovered that even 5,000 mile intervals are too short for the driving conditions and health of the vehicle.

Oil Consumption & Fuel Dilution in 6.0 Power Stroke Engines

Excessive oil consumption is not terribly common on 6.0 Power Stroke engines and care should be taken to identify and take into consideration oil loss from any external leaks. Oil consumption is generally regarded as excessive when greater than 1 quart of oil is loss over a 1,000 mile period of driving. We find this number to be a little high and would become concerned if any engine was losing 5+ quarts of oil between 5,000 mile oil change intervals. When oil consumption is an issue, it can generally be linked to 1 of 3 causes:

- Failure of one or more turbocharger seals (o-rings or oil seals) allowing engine oil to enter the intake air path or exhaust. Engine oil that leaks into the exhaust system can leave an oily, wet residue at the tailpipe. Engine oil that is entering the intake air path and being consumed in the combustion chamber will result in oil soaked intercooler piping boots and may produce visible gray smoke while the engine is running. Note that some oil in the intercooler boots is normal as oil mist enters the intake path through the CCV system.

- Leaking fuel injector/bad injector seal(s). When this condition occurs, engine oil doesn't directly enter the combustion chamber but often contaminates the fuel system. This can be identified by removing and inspecting the fuel filters; if they are dark in color, there is likely engine oil entering the fuel system due to a failed injector o-ring.

- Severely worn engine - a bad piston ring seal will allow excessive engine oil to stick to the cylinder wall and be consumed. The absolute method of verifying engine piston ring condition is by performing a compression test. A power balance or cylinder contribution test alone does not isolate a cylinder from the possibility of low contribution from a fuel system issue.

A critically clogged air filter can also cause excessive vacuum through the crankcase ventilation system, but this problem is not nearly as common on 6.0 Power Stroke engines as it is on 7.3 liter engines; the 6.0 employs a massive, high capacity air filter.

Fuel dilution is a common and normal affliction in all diesel engines. It is generally accepted that the threshold between normal and excessive fuel dilution is 5%; anything greater than 5% fuel in the engine oil (by volume) dictates an excessive amount. Excessive fuel dilution is a condition typically identified in an oil analysis, but it may also be noted by finding that the crankcase oil level is high. On a 15 quart system, 5% fuel dilution represents 3/4 of a quart of oil present in the crankcase. It can be caused by driving conditions, such as extended periods of idling or heavy towing. For the 6.0 Power Stroke, however, it is more often than not caused by a compromised fuel injector seal.

6.0 Power Stroke Engine Oil Selection

The 6.0 Power Stroke requires an engine oil that at minimum meets API CI-4 specifications. Modern CJ-4 and CK-4 category motor oils meet or exceed this specification, thus popular products available today should all be suitable lubricants. A synthetic motor oil is highly recommended and may prolong the life of the injection system by preventing stiction. Synthetic lubricants are more resilient to mechanical, thermal, and chemical breakdown. 6.0 Power Stroke engines subject engine oil to extremely high pressures and temperatures, thus selecting a quality synthetic engine oil is likely to have long term benefits including reduced wear.

Engine Oil Viscosity Chart

Note that in addition to identifying appropriate oil viscosities with relation to the anticipated ambient temperature, the 6.0 Power Stroke oil viscosity chart contains "acceptable" and "preferred" ranges for the most applicable grades, SAE 15W-40 and 10W-30. While an SAE 15W-40 is appropriate for all ambient temperatures 10° F and warmer, it is only preferred in ambient temperatures greater than 30° F and 10W-30 is listed as a more suitable alternative in ambient temperatures between 30° F and 10° F. The 10W-30 application range should be interpreted in the same fashion; we highly encourage selecting an engine oil that is listed as preferred for that temperature range.

Engine Oil Recommendations

Diesel Hub recommends the following Amsoil products for Ford Super Duty, Excursion, and commercial trucks equipped with the 6.0 Power Stroke diesel:

- Superior resilience against thermal breakdown and oil "cooking" in the turbocharger bearing passages

- Highly resistant to mechanical breakdown and shear forces resulting from high application pressures

- Improved HEUI injector reliability and resilience against stiction related injector problems

- Maximum protection again fuel dilution and chemical breakdown

- Improved oil flow and engine protection in sub-zero temperatures and during cold starts

Amsoil is a leading manufacturer of synthetic oils and lubricants, including a line of engine oils engineered to meet the harsh demands specific to diesel engines.

Engine Oil Additives

The 6.0 Power Stroke's fuel injectors are notoriously sensitive to stiction, a condition brought on by buildup and/or varnishing in the injector body. We have found that routinely using Archoil AR9100 friction modifier, an oil additive specifically engineered for the 7.3 and 6.0 Power Stroke engines, can prevent stiction and prolong fuel injector service life. When compared to the cost of replacing fuel injectors, treating the engine oil with this additive at a minimum of every-other oil change is a worthy investment.

Oil Change Parts List

| Part Description | Part Number(s) | Remarks |

|---|---|---|

| Engine oil filter | Motorcraft FL-2016 | [1] |

| Oil pan drain plug | Ford 8C3Z-6730-A | [2] |

| Oil pan drain plug gasket | DP-110303 | [1],[3] |

| Oil filter housing cap | Ford 3C3Z-6766-CA | [2] |

| Oil fill cap | Motorcraft EC-743 | [2] |

| Oil fill riser | Ford 4C4Z-6783-AA | [2] |

| Engine oil | Amsoil 15W-40 Signature Series synthetic diesel oil Amsoil 10W-30 Signature Series synthetic diesel oil |

--- |

| Engine oil additive | Archoil AR9100 friction modifier | --- |

[1] - Replacement of this part is mandatory.

[2] - Replacement of this part is optional; inspect and replace if damaged.

[3] - Crush type oil pan drain plug gaskets are designed for one time use; reused gaskets

may be highly susceptible to leak.

6.0 Power Stroke Oil Change Procedures

Click any thumbnail to view high resolution, full screen image- Park the vehicle on a level surface, set the parking brake, and allow the engine cool completely.

- Locate the drain plug on the bottom portion of the engine oil pan.

- Place a suitable drain pan (minimum 15 quart capacity) below the oil pan drain plug.

- Remove the drain plug with a 19 mm socket or wrench and allow the engine oil to drain completely.

- Locate the oil filter housing on the top of the engine between the turbocharger and intake manifold air horn.

- Completely loosen the oil filter housing cap with a 36 mm socket.

- Pull the oil filter and cap straight upwards to remove it from the filter housing. Keep the filter assembly vertical as you remove it as not to damage the plastic stand-pipe in center.

- Separate the oil filter from the cap by pulling the two segments apart; it will snap loose with light to moderate pulling force.

- Liberally coat the new oil filter cap o-ring with clean motor oil, then install it onto the cap.

- Install the new oil filter into the cap; note that the oil filter clips into the cap. The opening (hole) in the filter should be positioned at the bottom, away from the cap.

- Install the new oil filter, now secured to the cap, buy sliding it over the stand-pipe in the filter housing. Torque the cap to 19 ft-lbs (25 Nm); do not overtighten.

- Thoroughly clean the oil pan drain plug and inspect the threads for damage. The OEM drain plugs have a magnetic tip, so be sure to clear it of any debris.

- Install a new gasket onto the drain plug.

- Once the engine oil has drained completely, reinstall the oil pan drain plug. After starting by hand, snug down and then torque to 18 ft-lbs; do not overtighten.

- Clean any oil residue from around the drain plug/washer sealing area so that a leak can be easily detected.

- Locate the oil fill at the rear of the passenger side of the engine.

- Fill the crankcase with 15 quarts of motor oil through the oil fill tube; a funnel is recommended to avoid spillage.

- Pull and clean the engine oil level indicator (dipstick), then reinsert into the dipstick tube.

- Pull the engine oil level indicator once more and verify the engine oil level is correct.

- Start engine and check for leaks around the drain plug and oil filter cap sealing areas.

- After taking the vehicle for a short drive, recheck for leaks and verify correct engine oil level once more.