A diesel-hybrid powertrain configuration is not a new concept, but "hybrid" is an umbrella term that encompasses many diesel-electric and gas-electric propulsion strategies. Locomotives, for example, commonly utilize a diesel-electric drive system which could be classified as a hybrid even though it may not fit the traditional mold with regard to hybrid cars and trucks. In fact, it has been well over a century since the first diesel-electric locomotive prototype was developed.

Although Europe has several examples, a diesel-hybrid car or truck has yet to be presented in the United States. This powertrain configuration faces many unique challenges and in some instances might even be regarded as redundant since the diesel cycle is already significantly more efficient. Furthermore, the complexity of the hybrid arrangement increases the premium cost of a typical diesel powertrain. But if regulators continue to push for more stringent emissions regulations, it may be a possible pathway to avoid or postpone full electrification.

Types of Hybrid Propulsion

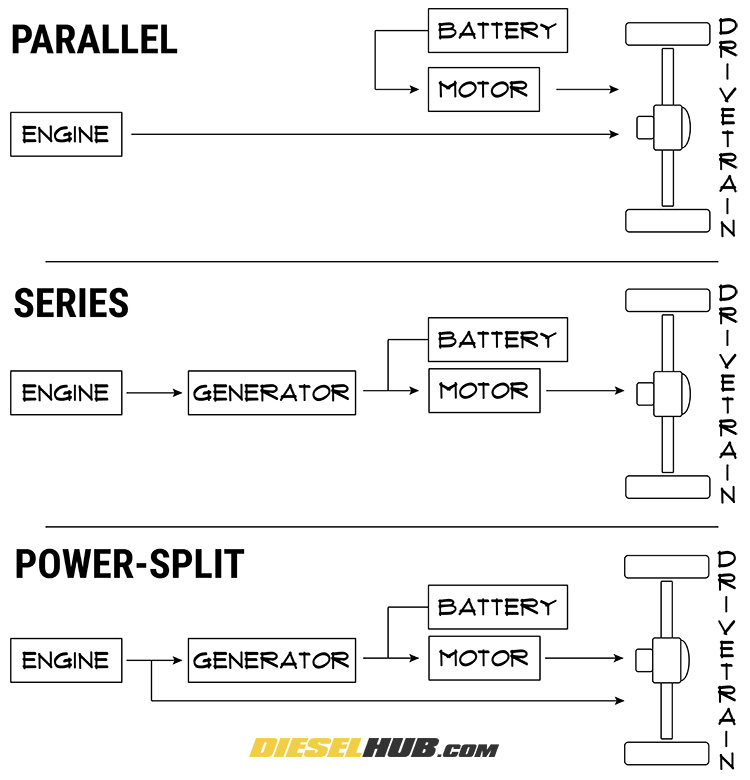

There are three primary types of hybrid propulsion systems - parallel, series, and power-split. In a parallel system both an engine and an electric motor provide propulsion to the drivetrain. The engine or the motor can power the drivetrain independently, or the engine and motor can power the drivetrain simultaneously. Powering the motor via an on-board battery can provide significantly improved fuel economy by relying solely on electric drive, or by supplementing engine power by allowing the electric motor to carry a portion of the propulsive load.

In a series hybrid system the drivetrain is powered entirely by an electric motor and an engine is used to drive a generator - there is no direct mechanical connection between the combustion engine and drive wheels. The engine can therefore be used to power the motor, recharge the on-board battery, or both simultaneously. As in the parallel system powering the electric motor via an on-board battery can provide significant improvements in fuel economy, and the engine can be used to energize the motor and recharge the battery on an on-demand basis.

A power split system is a combination of a parallel and series hybrid system. The engine drives both a generator and the drivetrain and the electric motor is connected to the drivetrain parallel to the engine. While this system is more complex, it is also the most versatile. The engine can directly drive the wheels, provide power generation to recharge the battery or drive the electric motor, or any combination of these operating modes.

Mild Hybrid

A mild hybrid system is a type of series layout, but a combination electric motor/generator drives the crankshaft of the engine is not otherwise connected to the drivetrain. The Ram eTorque system utilized on the 3.6 liter V-6 and 5.7 liter Hemi engines is a modern example of such a system, which drives the crankshaft via a belt and pulley system. The electric motor replaces the alternator in these applications and charges both the vehicle battery and a cabin mounted drive battery.

The mild hybrid system is a form of electric assist to the internal combustion engine and the vehicle cannot be driven solely by electric propulsion. Instead, the electric motor is used to reduce load on the engine or increase total torque output. One benefit of the system is that it is not nearly as expensive as a traditional hybrid powertrain, nor does it add a significant amount of weight to the vehicle. It also adds regenerative capabilities such that waste energy can be captured in the form of stored battery power during deceleration. Supplementing engine power can increase fuel economy and reduce emissions, but the effectiveness of these systems is limited by the size and power of the electric motor and battery pack.

Benefits

At face value the obvious benefits to a hybrid diesel system are reduced fuel consumption and tailpipe emissions. There are several approaches that may be used to evaluate potential increases in fuel economy and reductions in emissions, but the real world implications will be largely variable and dependent on a number of uncontrollable factors. Additionally, it requires accepting common models that formulate relationships between petroleum fuel usage and electrical power generation.

A distinction must be made between tailpipe emissions and cumulative vehicle emissions. Tailpipe emissions refers to the exhaust products produced by fuel consumption and conversion in an internal combustion engine. Cumulative emissions refers to the total emissions produced in the generation of energy for a given unit of travel, or the sum of the tailpipe emissions and those emitted in the generation of power used to recharge a vehicle battery from a utility grid. Furthermore, the impact of driving conditions on total vehicle emissions and fuel economy values is significant and must also be weighed.

Negating the emissions related to vehicle manufacturing, the total reduction in emissions has many variables and is heavily dependent on the source of power used to recharge. Renewable technologies, primarily solar and hydroelectric, fall into the "clean" category while coal is amongst the dirtiest sources of energy. Natural gas and nuclear energy are other common sources of power generation. Wind turbines are also a source of energy, however the actual life-cycle carbon footprint produced by these machines is widely debated and has been the source of broad controversy.

For a hybrid diesel system, fuel consumption would be entirely dependent on how often the diesel engine is operated and the conditions under which it is operated. Total fuel economy must take into consideration fuel and energy consumption, specifically if vehicle propulsion is dependent on power received from a utility grid to recharge a battery. If the plug-in aspect of the hybrid powertrain is removed, fuel economy becomes entirely dependent on fuel consumption as any electrical power used by the motor was ultimately produced by the diesel engine.

The electric vehicle sector typically uses the term miles per gallon gasoline equivalent (MPGe) in applying the traditional fuel economy metric to EVs. Furthermore, the U.S. Department of Energy provides gasoline gallon equivalents (GGE) for various fuel and energy sources. 1 GGE is the equivalent of 1.14 gallons of diesel fuel and 0.3 kWh of electric power. These conversion factors can be useful in devising a comparison between electric vehicle energy usage and fuel consumption in ICE propelled vehicles.

Another consideration on the subject of fuel economy is the energy recovery capabilities of the electric motor. This strategy is referred to as regenerative braking and is possible in a hybrid system because the electric drive motor can also function as a generator; when it is isn't receiving power, it is producing it. Thus, it is possible to capture and store waste energy during deceleration, contributing to increases in overall efficiency. In a standard engine propelled vehicle, energy is released through the brake system in the form of heat when the vehicle is slowed. In a hybrid drive system, a portion of this waste can be converted into usable energy that is stored for later use.

Furthermore, it is important to recognize that a diesel engine may run at entirely different operating conditions in a hybrid system. If an electric motor is used as the primary or sole source of propulsion to the drive wheels, the diesel engine may run at a constant speed for long periods of time, run at more consistently low engine speeds, and even avoid high RPM conditions altogether. It is possible, under the right conditions, that the engine speed remains constant and only the engine load is variable. An adequately charged battery could provide additional energy required by the electric motor during periods of high load or acceleration when engine power generation alone is insufficient. A diesel engine operating at constant speed is significantly more efficient than one in which the speed changes frequently. This would contribute to improved efficiency and lower tailpipe emissions.

With these considerations we can begin to formulate scenarios where a diesel hybrid system would be beneficial in improving fuel economy and reducing emissions. Unfortunately there are many design pathways and unknown variables that make it difficult to draw a conclusion with regard to actual or even estimated savings. Calculating this information would need to begin with a proposed hybrid diesel design. What is certain is that the hybrid system has, at the very least, the potential to provide reduced tailpipe emissions and improved fuel economy.

Challenges

The diesel hybrid concept is not without its share of challenges and this is apparent in the obvious lack of real world examples. Save for locomotives, many of which use an electric motive power propulsion system, there are no diesel hybrid vehicle examples in the United States and only a few small examples overseas. The major challenges that such a system faces include:

- Vehicle price

- Vehicle curb weight

- Reaching and maintaining engine operating temperature

- Redundancy

Diesel engines are more expensive to manufacturer than gasoline engines or a purely electric powertrain, thus they are already purchased at a premium. Furthermore, the exhaust aftertreatment systems required for these engines extends the price even higher. Add a battery, an electric motor, a generator, miles of wiring, and a specialized transmission to this premium and you have one very expensive vehicle. This high price serves as an entry barrier to the end consumer and a liability to the manufacturer.

Diesel engines are also significantly heavier than comparable gasoline engines, even with more recent weight-saving strategies. The exhaust aftertreatment system required for modern diesels is also heavy and adds to overall vehicle weight. Balancing battery storage capacity and total vehicle weight therefore becomes a significant give-and-take, but a high curb weight is nearly unavoidable and negatively affects overall efficiency. Imagining all these components packaged in a full-size pickup truck without sacrificing current engine output levels would require adding an unreasonable amount of weight, diminishing payload capacities and lessening practicality.

A significant consideration in diesel engine efficiency and emissions is engine operating temperature. Compression ignition engines operate most efficiency within a certain operating temperature range and low operating temperatures contribute to incomplete or poor combustion characteristics. This results in greater tailpipe emissions and increased fuel consumption. The catalysts in the exhaust aftertreatment also require a minimum exhaust temperature to function efficiently, and diesel particulate filter regeneration cycles require even more heat.

Maintaining a minimum engine operating temperature could prove difficult if the engine load is decreased due to parallel operation with an electric motor, or if the engine undergoes frequent start and shut-down cycles in supplementing an electric propulsion mode to meet driving conditions. Fuel dilution, the intrusion of unburned diesel fuel into the crankcase, is a common concern in diesel engines and would be also be a challenge to control at low operating temperatures. This could require more frequent service intervals, extending the overall cost-of-ownership.

Redundancy is also at the top of the diesel hybrid discussion since diesel engines have a significant advantage over gasoline engines, particular at low engine loads and lean operation. We can highlight many modern examples, including fullsize pickup trucks from the Big 3 automakers that earned highway fuel economy ratings in excess of 30 mpg. The Volkswagen Jetta, once rated at near 45 mpg on the highway, is another example of an extremely efficient vehicle that nearly bests early gasoline hybrid platforms. At what premium does a diesel hybrid become a viable, financially attractive powertrain option?

Summary

Start-stop technology will long precede the hybrid model in the 3/4 and 1 ton pickup truck categories. This strategy has already been implemented on diesel engines in lighter vehicles, including those powered by the 3.0 liter EcoDiesel and 3.0 liter Duramax, as a means to extract an additional mile per gallon. 3/4 and 1 ton pickup trucks do not have to adhere to fuel economy standards, but this segment is readily persuaded by emissions laws.

Diesel hybrids are uncommon not because of a single reason, but for a combination of reasons. Picking one of the challenges is therefore not possible. In a mild hybrid system, the biggest problem becomes redundancy - the benefits are not high enough to justify the cost.

However, if a hybrid system becomes necessary to meet regulations the mild hybrid has several inherent benefits - energy recapture, small packaging size, minimal weight addition, lower cost and complexity than a full hybrid, and integrates well with automatic start-stop technology. However, is the benefit to cost ratio sufficient enough? Only if there is no other option and it becomes a necessity. I highly doubt there are sufficient efficiency gains to offset the cost, and one must consider the additional maintenance and repair costs incurred down-the-road.

Things could change in time; technology tends to become more affordable as manufacturering solutions and lower material costs emerge in the wake of increased demand and research. If restrictions on emissions and expectations on fuel economy continue to grow increasingly stringent automakers will need to respond with practical solutions - the full electrification model has thus far failed to meet the broader transportation needs in the U.S. but hybrid systems may be a viable stepping stone.