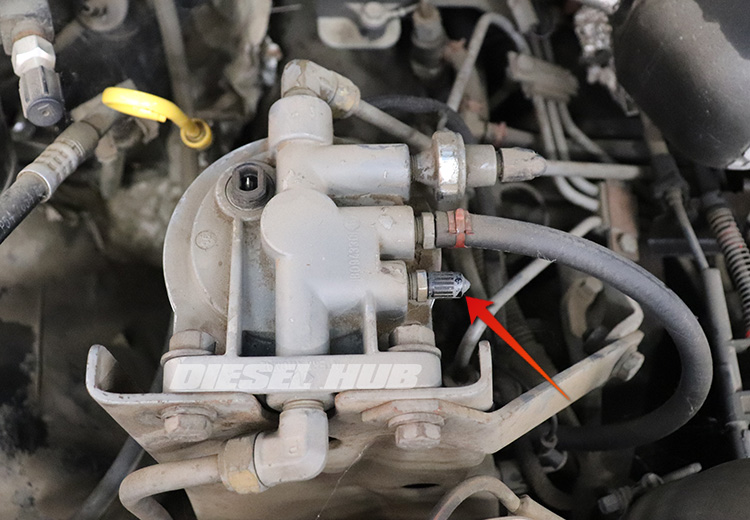

Fuel pressure is checked at the filter base on both the 6.9 and 7.3 liter IDI engines. The test port, which can also be used to bleed air from the housing, is located next to the return orifice on the top of the filter base. To prevent contamination, pressure is tested on the unfiltered side of the fuel supply and thus represents actual pressure on the outlet of the fuel pump. A clogged fuel filter could, however, prevent fuel flow to the injection pump despite reading acceptable fuel pressure at the housing. Furthermore, the fuel flowrate is equally important to actual system performance.

The factory fuel pressure test port requires the use of a Ford style adapter. While not entirely uncommon, this adapter isn't always included in pressure test equipment sets and is becoming increasingly obsolete because it is primarily found on older vehicles. In lieu of acquiring this adapter, an updated fuel pressure test port is available that will convert to the more common 1/4 flare style fitting that often does not require any adapter whatsoever.

Gauge graduation is an important consideration; a test gauge that reads 100 psi will not have the fine graduation marks to read lower pressures and monitor pressure fluctuations accurately. A gauge with a maximum 10 psi pressure reading and finer graduations will provide more accurate and easier to read measurements. Replacement gauges that use common 1/8 or 1/4 inch NPT connections are widely available and reasonably priced, but be sure to verify they are fuel rated.

Testing fuel pressure is as simple as attaching a test gauge to the fitting on the filter base and ensuring that the hose is positioned such that it cannot come into contact with the fan or accessory drive belt/components. Fuel pressure can be tested while cranking the engine or with the engine running. Ford specifies a minimum 2 psi is at idle but a minimum 5 psi is more common and realistic for a fuel system in good overall condition. At elevated engine speed the 2 psi specification becomes more practical.

Furthermore, the lift pump is required to flow a minimum 1 pint of fuel to the filter housing in a 30 second window. The fuel pressure reading is going to fluctuate with the pumping action of the cam-driven fuel pump, which performs one pumping action per camshaft rotation. These pulses in fuel pressure will be spaced closer and closer together as engine speed increases, resulting in more consistent pressure output. The pressure pulses should be fairly consistent for any given engine speed, thus the duration and magnitude of the pulsations should remain more-or-less constant.