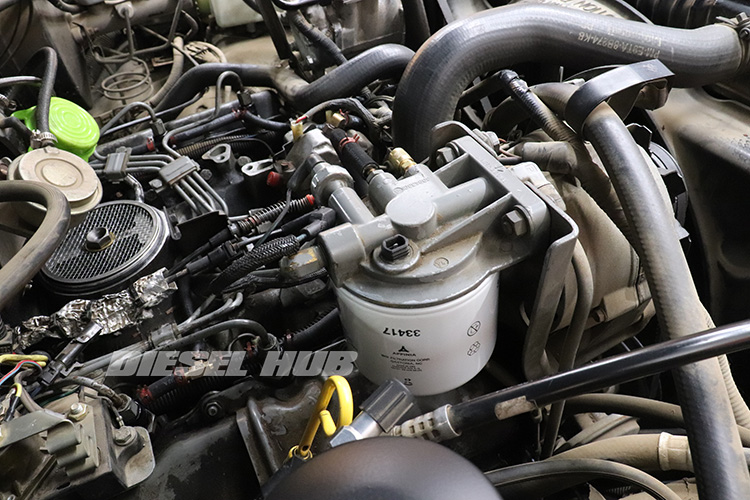

The fuel heater or fuel filter heater is mounted in the filter base on the 7.3 liter IDI diesel. It uses a pass-thru connector that protrudes through the top of the filter base and is sealed to the base by at least one ring. Early style heating elements sealed to the base with two o-rings, late style elements were sealed with a single o-ring. The element itself is sandwiched between the top of the filter base and the brass filter adapter beneath it. 6.9 liter IDI engines do not have a fuel heater. For those interested in eliminating this component and the chance of it leaking in the future, see: 7.3 IDI fuel heater delete.

When the o-ring(s) get old, brittle, and fail, a fuel leak will ensue. The severity of this leak can range from minute to significant flow, it all depends on the condition of the o-ring and how it failed. Removing the element and replacing the o-ring begins with draining the fuel-water separator at the base of the fuel filter, and then removing the fuel filter. Place rags beneath filter to prevent fuel drips and residual fuel leaks from running down the side of the engine or pooling in the engine valley.

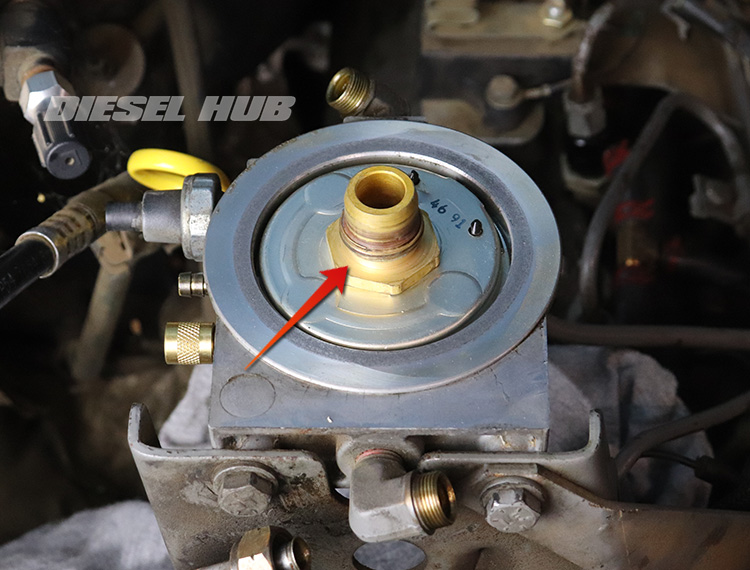

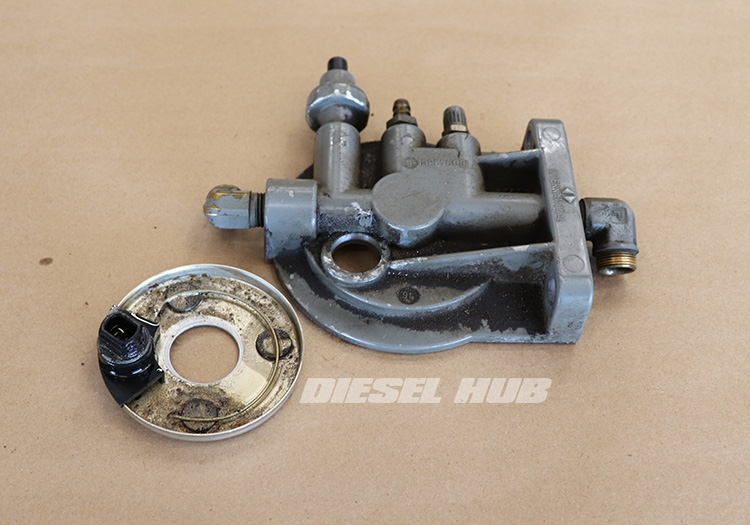

The next step is to remove the threaded filter adapter with a 1-1/4 inch wrench or socket (figure 3, below). For the sake of clarification, this base has been removed and flipped over to better explain the procedure, but it can be removed without flipping the filter base. Since you have the filter removed, it may be worthwhile to disconnect the inlet (3/4 inch wrench) and outlet (5/8 inch wrench) lines to the filter base so that they can also be resealed at this time. The brass adapter uses standard rotation threads.

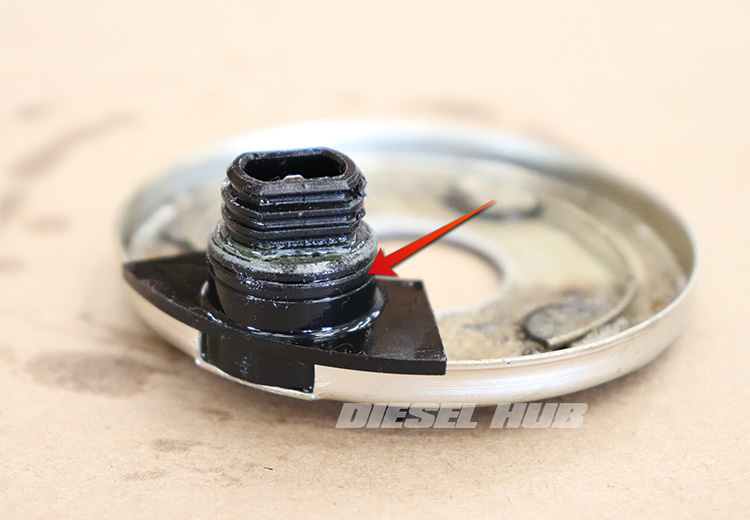

Once the adapter is removed from the filter base, the heating element can be removed by pushing the pass-thru connector through the small hole in the filter base. Consider cleaning the heater if it is harboring debris on the upper part of the mounting plate (figure 4, below). Use an aerosol solvent that is plastic safe as not to damage the connector - brake cleaner and carb and choke cleaner will attack the plastic connector.

Remove the old o-ring(s) with a pick but be careful not to put scratches on the sealing surfaces as this could prevent the new o-ring from sealing properly. Don't be surprised if the old o-ring is brittle and comes off in pieces, but make sure everything is clean before the new o-ring is installed.

Liberally coat the new o-ring(s) in clean motor oil and then install it in reverse order. Dieselply kit 160101 is being used here. Lubricating the o-ring will prevent it from binding while it is stretched over the connector and helps to evenly distribute compressive forces when the heater is reinstalled. Reinstall the fuel heater into the filter base and verify that the o-ring(s) seated then reinstall the brass filter adapter, using high strength thread-locker on its threads. Tighten the adapter snugly, then torque to 50 ft-lbs.

If the filter base was removed or the fuel lines have been disconnected, the compression seals will likely need to be replaced (recommend upgraded Viton sleeves, DP-1611K). Coat the inside of each sleeve with clean motor oil before installing onto the fuel line, and coat the outside before tightening down the fitting. This fitting system is meant to remain flexible enough to allow for engine vibration and movement, but can be prone to leaks if the sleeves are not in good condition.