Applicable Models:

1994.5 - 1997 Ford F-250, F-350, F-Super Duty

1999 - 2003 Ford F-250, F-350, F-450, F-550 Super Duty

2000 - 2003 Ford Excursion

1995 - 1999 Ford Econoline E-350

2000 - 2003 Ford F-650, F-750

2000 - 2003 Econoline E-350, E-450, E-550

Applicable Engine(s):

7.3 liter Power Stroke V-8 (7.3 DIT)

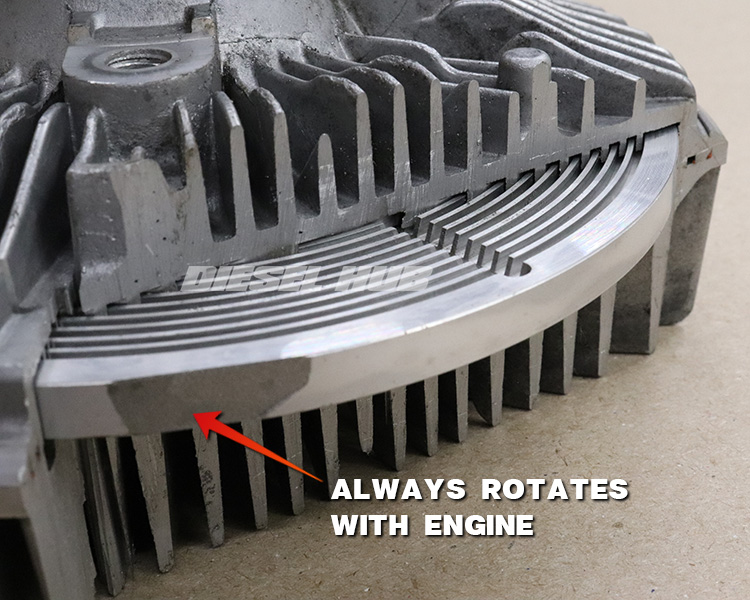

The 7.3 Power Stroke engine utilizes a common viscous type variable speed fan clutch with a thermo-mechanical speed control mechanism. A thermostatic bi-metal spring at the face of the fan clutch ultimately controls the movements of a viscous fluid between a reservoir and the working chamber of the clutch. As air temperature at the face of the clutch increases beyond a set threshold, the amount of fluid flowing into the working chamber increases, proportionately increasing the shear forces between a series of independently rotating grooved plates. As these shear forces increase, the fan speed (output) increases relative the engine speed (input). For an in-depth look into the operation of a viscous fan clutch, see: How a viscous fan clutch works. Figure 1 below is a cutaway view of the fan clutch on a 7.3 Power Stroke engine, showing the shear plates and working chamber.

Fan Clutch Diagnostics

Under ideal conditions the radiator receives a constant and adequate supply of ambient air flow across its fins, removing heat from the engine coolant. Certain conditions, generally high engine load and low vehicle speed, can result in insufficient heat removal through the radiator. The fan clutch is specifically designed to provide supplemental airflow across the radiator during these conditions. Thus, an inoperable fan clutch could contribute to or fail to prevent an overheating condition.

However, more often than not fan clutches are replaced because they become stuck and the fan runs at all times. The operation of the fan consumes a significant amount of energy, giving the indication of a low power or poor response condition. Disconnecting the fan from the engine is vital to minimizing parasitic losses when the fan is not needed and maximizes efficiency. When a fan clutch becomes stuck on, engine power and fuel efficiency can be greatly impacted. Additionally, the cooling fan is not exactly quiet - a continuous loud whirring noise that increases and decreases with engine speed is a good indication that a fan clutch is not operating properly.

Never attempt to touch a fan or any other accessory drive component while the engine is running - severe injury is imminent. To diagnose a fan clutch on the 7.3 Power Stroke, observe the following steps:

- If the engine coolant temperature is running hotter than normal and/or there is an overheating condition, pay attention to whether or not the fan kicked on - the sound of the fan running is undeniable. If the fan clutch never engaged, it may be faulty.

- With the engine off, visually inspect the fan clutch, ensuring that there are no obvious signs of fluid leaking from the housing and that the thermostatic spring at the face is not broken. Both of these conditions would indicate that the fan clutch needs to be replaced.

- With the engine off, rotate the fan by hand - it should rotate with some light resistance. If the fan clutch rotates with no resistance, it has likely lost its fluid and needs to be replaced. If the fan clutch rotates with high resistance or is locked up (wants to spin the pulley/belt, cannot rotate by hand), it may be mechanically bound and needs to be replaced.

Note that overheating conditions are more consistently related to coolant flow -. low engine coolant level, faulty thermostat, water pump, etc - and not the fan clutch. Heat and fluid loss are the two primary factors that contribute to fan clutch failures.

Fan Clutch Part Numbers & Removal Tools

Fan blade assemblies are entirely reusable, but replacement should be considered if the blades are damaged and/or it appears that it has contacted another component. Early engines utilized a metal fan while 1999 and newer engines have plastic fan blades. These components are becoming obsolete for 1994 to 1997 model engines and thus factory Ford parts may be more difficult to obtain.

| Component | Part Number(s) |

|---|---|

| Fan clutch, 1994 - 1997 | Ford F5TZ-8A616-KB |

| Fan assembly, 1994 - 1997 | Ford F4TZ-8600-C |

| Fan clutch, 1999 - 2003 | Motorcraft YB-3157 Ford AU2Z-8A616-L |

| Fan assembly, 1999 - 2003 | Motorcraft YA-225 |

Required Tools

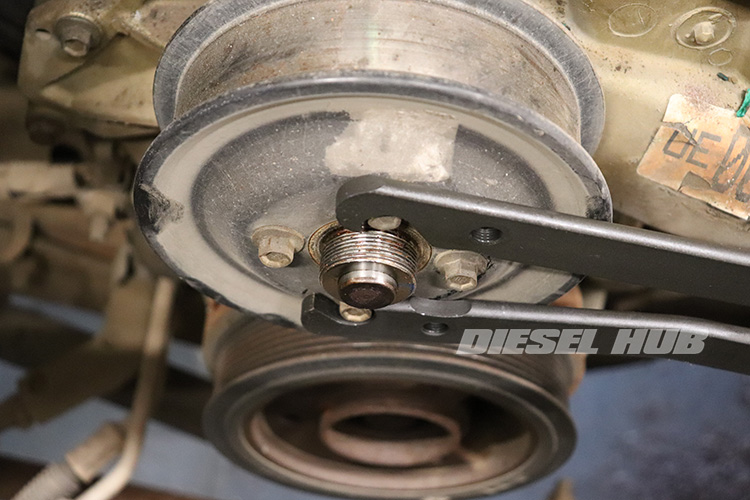

Removing and installing the fan clutch requires two special tools - one to loosen/tighten the nut integrated into the input shaft of the fan clutch and another to hold the fan pulley. The nut is managed with a 47 mm fan clutch wrench, which is a common tool shared across many applications. The fan clutch/water pump pulley can be held stationary with the specific Ford tool (OTC 303-478, figure 2 below) or a universal pulley holder (Gearwrench 3900, figure 3 below). The figures below specifically show how holding the pulley is accomplished with each tool type.

The universal tool option does not secure the pulley as easily or securely as the OTC/Ford Rotunda option, but either tool will suffice. A workaround for some is to loosen and apply final torque to the fan clutch shaft by using a pneumatic hammer aimed at one corner of the flats on the shaft. We recommend obtaining the proper tools for the job and replacing the fan clutch using the intended methodology. If the fan clutch shaft is bound and cannot be loosened with a wrench, the pneumatic hammer may be worth trying. When all options have been exasperated and the clutch shaft will not unthread, remove the entire water pump with the fan clutch attached.

How to Replace the Fan Clutch on a 7.3 Power Stroke Engine

Click any thumbnail to view fullsize, detailed image

- Disconnect both negative battery cables.

- Remove the degas bottle cap.

- Drain the radiator into a suitable container or container(s). The drain valve is located on the lower, driver side of the radiator. Engine coolant can be reused it is in good condition and collected in clean containers.

- Disconnect the degas bottle inlet hose at the tank.

- Disconnect the degas bottle drain hose at the radiator (next to the lower radiator hose).

- Remove the degas bottle upper mounting bolt.

- Remove the (2) lower degas bottle retaining bolts.

- Maneuver the degas bottle upwards and out of the engine compartment.

- Remove the passenger side fan shroud retaining bolt.

- Let the fan shroud float in place; at this point, it is only held in place by small tabs on either side of the base.

- If the shroud seems to be in the way, reinstall one retaining bolt hand tight so that it can be readily removed when required.

- Install an appropriate tool to secure the water pump pulley; tool options were previously discussed above.

- Use a 47 mm fan clutch wrench to rotate the large nut at the base of its shaft counterclockwise (looking into the fan from the front of the vehicle - threads are standard rotation).

- Once the fan clutch nut has been broken loose, completely unthread the assembly from the water pump.

- Carefully remove the fan, fan clutch, and fan shroud together.

- Inspect the water pump shaft threads for damage.

- Remove the fan from the old clutch and install it onto the new clutch.

- Torque the cooling fan mounting bolts to 18 ft-lbs in an alternating pattern.

- Install the new fan clutch/fan assembly in reverse order.