Realistically, it is the fuel injectors that are of high risk of damage due to running dry. If the high pressure oil pump (HPOP) reservoir was previously drained, it should be correctly replenished with new, clean motor oil. This is going to supply the HPOP with oil almost instantly after the engine is cranked for the first time and the the low pressure oil pump (lube oil pump) will begin resupplying the reservoir moments after the engine begins cranking. However, air in the hoses and pump is going to be forced into the cylinder head oil rails and ultimately to each fuel injector. The same is going to happen within the fuel galleries and into the fuel side of the injectors if the fuel bowl/lines have been removed.

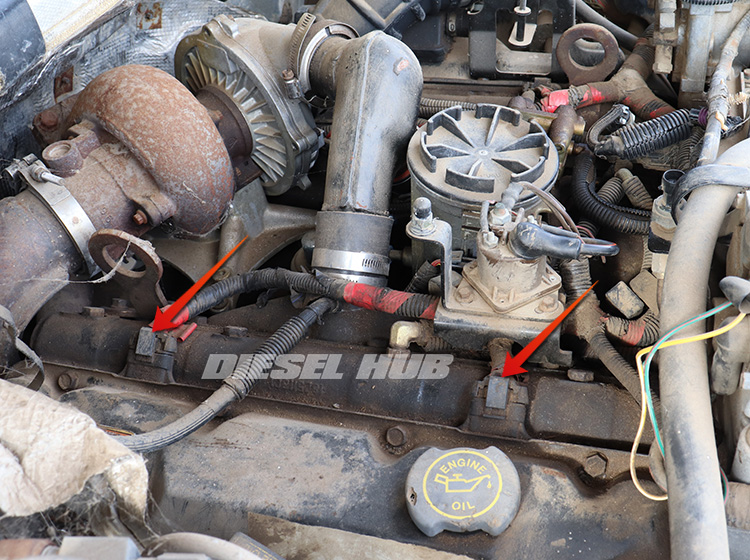

To protect the fuel injectors, priming the systems in a safe manner is accomplished by disabling or bypassing the them. Jumping the starter solenoid with a momentary switch will crank the engine over without turning the system to "run", so the IDM and glow plug systems will never power on. While this is a viable solution in early engines with a mechanical fuel pump, it is inefficient in later engines with an electric fuel pump because the fuel pump would normally run for a brief period during the glow plug preheat cycle (which is being bypassed). Figure 1 below depicts jumping the fender mounted starter relay to crank the engine.

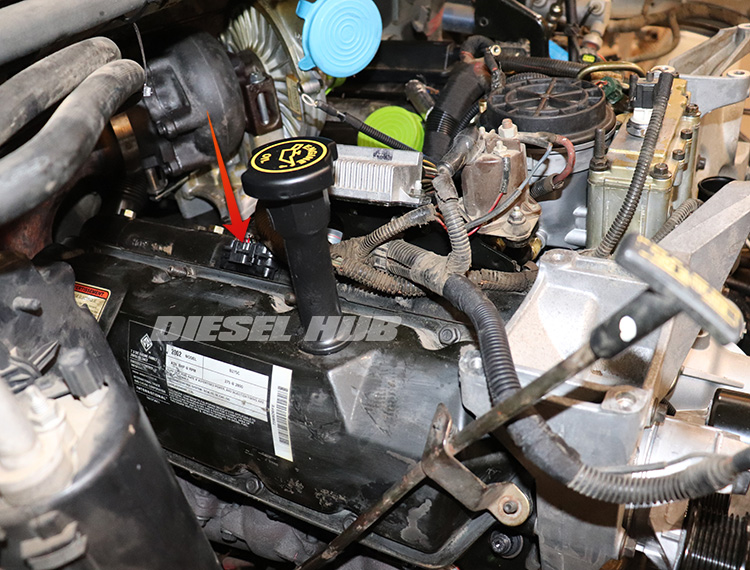

Another method that works on both early and late model year engines is to unplug the under valve cover harness (UVCH) connectors. This is the pass-through connector in the valve cover gasket that connects the engine wiring harness to the fuel injector and glow plug harness hidden beneath the valve cover. Early engines have (2) connectors per cylinder head while late engines have (1) large connector per cylinder head (figures 2 and 3 below).

With the UVCH connectors unplugged the engine can be cranked over using the key. Switching to the "run" position in later engines will allow the electric fuel pump to be powered on, thereby priming the fuel system. Both the oil and fuel system will prime while the engine is cranked. The fuel injectors will be disabled and the glow plug system will draw no power because there is no continuity to the actual glow plugs.

Crank the engine several times in roughly 10 second cycles, followed by a 10 minute cool down to prevent starter damage. Repeat 3 to 5 times, then reconnect the UVCH connectors and start the engine. If the engine won't stay running or stumbles for more than 10 seconds, prime the system once more. There is no need to go through the "preheat" cycle while priming on early engines because the fuel pump is mechanical and requires the engine to crank.